All Agent

-

Read More

Electrode Boilers and Heat Storage

Electrode Boilers and Heat StorageElectrode Boilers and Heat Storage

Electrode Boiler with Thermal Energy Storage

Shuangliang’s electrode boiler combined with thermal energy storage technology is especially suitable for applications with fixed cycles or intermittent demands for steam or thermal energy.

The system adopts the following technical approach:

The electrode boiler generates steam using electricity, which can come from solar panels (green power) or the power grid.

The thermal energy storage system stores heat in the form of high-pressure hot water inside an insulated tank. This stored energy can be released when steam or heat is needed.

Key Advantages:

Utilizes low-cost electricity (e.g., off-peak night-time electricity or surplus renewable energy) for heat generation.

Stores energy during low-demand periods and releases steam or thermal energy during peak demand, maximizing energy efficiency and cost savings. -

Read More

Air Cooling & Drift Elimination Towers

Air Cooling & Drift Elimination TowersAir Cooling & Drift Elimination Towers

Advanced Industrial Cooling Solutions from Shuangliang Group

With strong R&D and manufacturing capabilities, Shuangliang Group offers a full range of industrial circulating water cooling solutions, including:

High-Efficiency Air Coolers for Circulating Water

✔ Compared with traditional horizontal aluminum finned air coolers, our solutions offer significant advantages in cost, weight, air resistance (energy consumption), ease of cleaning and maintenance, corrosion resistance, and space efficiency.

Water-Saving and Anti-Drift Cooling Towers

✔ Separated water-saving anti-drift cooling towers

✔ Horizontally arranged dry-wet separation towers

✔ Vertically arranged dry-wet separation towers

✔ L-shaped hybrid dry-wet closed cooling towers

✔ Overlapping hybrid dry-wet cooling towers

✔ Modular hybrid dry-wet cooling towers

✔ Natural draft cooling towers

Water-Saving Retrofit Solutions for Existing Open Cooling Towers

✔ Utilizing our proprietary technologies and products, we offer retrofit solutions for open-type cooling towers to enhance water-saving and anti-drift (white smoke elimination) performance.

✔ Achievable results include:

Peak season water saving

Year-round anti-drift and white plume elimination

Variable frequency fan control

Energy-saving fan operation

Our Core Cooling Technology: Proprietary High-Efficiency Fin Tube Bundles

All our cooling products are built upon Shuangliang’s independently developed and manufactured high-efficiency finned tube bundles, with the following technical advantages:

High-efficiency heat exchange components

Low air resistance and reduced fan power consumption

Minimal heat exchange efficiency degradation over time

Strong corrosion resistance

Easy and convenient tube cleaning

100% air-tightness tested tube bundles

Intelligent control systems for maximum energy and water savings -

Read More

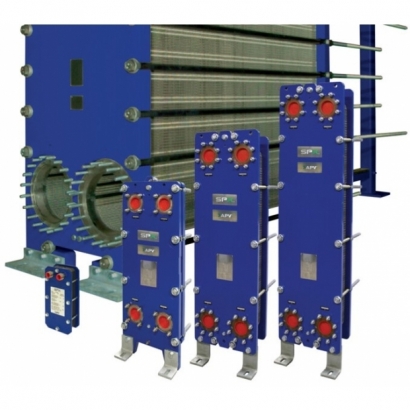

SPX FLOW Genuine Spare Parts & Services

SPX FLOW Genuine Spare Parts & ServicesSPX FLOW Genuine Spare Parts & Services

We supply OEM spare parts for APV and WCB equipment, ensuring optimal performance and reliability. All parts are engineered for compatibility and extended service life.

We also offer expert onsite replacement, inspection, and commissioning to maintain uptime and product quality.

Choose SPX FLOW parts for lasting performance.

Contact us for technical support and service coordination.

-

Read More

APV UHT Sterilization System

APV UHT Sterilization SystemAPV UHT Sterilization System

APV UHT (Ultra High Temperature) Sterilization System

Delivers rapid and uniform sterilization for milk and liquid foods (135–150 °C), preserving flavor. Available in tubular, plate, or scraped-surface designs to match product needs.

Further information is available on the official SPX FLOW website:UHT system

Features:

Rapid heating/cooling minimizes thermal impact.

Fully automated CIP/SIP; HACCP and 3-A compliant.

Supports DSI or indirect (PHE/SSHE) heat modules.

Modular setup integrates with aseptic filling. -

Read More

APV Double Tube Sheet Cleanable Heat Exchanger

APV Double Tube Sheet Cleanable Heat ExchangerAPV Double Tube Sheet Cleanable Heat Exchanger

SPX FLOW APV ParaTube®

For ultra-hygienic applications in food, biotech, and pharma. DTS design ensures full separation of product and utility fluids, with independent leak detection.

Further information is available on the official SPX FLOW website:APV ParaTube®

Key Features:

DTS separation; 3-A, EHEDG, ASME BPE, FDA compliant.

Tube options: 316L, duplex, titanium.

Zero dead zones; CIP/SIP ready.

Configurations: multi/single/U/bent tubes.

Ideal for WFI, amino acids, fermentation, vaccines, injectables. -

Read More

Scraped Surface Heat Exchanger

Scraped Surface Heat ExchangerScraped Surface Heat Exchanger

APV Scraped Surface Heat Exchanger

Designed for high-viscosity and particulate-laden products, the APV scraped surface heat exchanger is ideal for food and pharmaceutical applications. Integrated scraper blades prevent fouling, improve heat transfer, and ensure consistent product quality.

Further information is available on the official SPX FLOW website:VT / HT Origin Series、VT+/HT+ Series

Key Features:

Versatile Application: Suitable for a broad viscosity range, with or without particulates.

Hygienic Design: Complies with CIP/SIP and aseptic standards.

Serviceability: Modular design enables quick access and fast scraper/seal replacement.

Robust Construction: 316L or duplex stainless steel, built for high pressure and temperature.

WCB Votator® II Horizontal Scraped Surface Heat Exchanger

Provides continuous, uniform thermal processing for viscous products. Offers high efficiency, hygienic operation, and straightforward maintenance.

Further information is available on the official SPX FLOW website:Votator® II Horizontal

Key Features:

High Pressure Rated: Standard up to 600 psi (42 bar), UStamp up to 800 psi (56 bar) at 204 °C.

Optimized Scraping: Continuous blade action minimizes fouling; PEEK™ options available.

Sanitary Construction: Meets 3-A, ASME, PED, FDA, CE; available in 316L, hard chrome, nickel, or duplex.

Direct-Drive Motor: Nord gear motor (5.5–22 kW), no belts or couplings.

Quick Service: VLock head, spline shaft, and removable heat tubes.

XHD Version: Handles viscosities up to 1,000,000 cP with enhanced torque and durability.

Applications: For fluids with particulates, crystallization tendency, or thermal sensitivity—such as sauces, pastes, and chocolate. Also suitable for cooling, sterilization, mixing, and crystallization processes. Widely used in industries such as food and dairy, edible oils and sauces, chemicals, pharmaceuticals, personal care, sugar, and meat processing.

-

Read More

High-Efficiency Screw Chiller WCFX-E

High-Efficiency Screw Chiller WCFX-EHigh-Efficiency Screw Chiller WCFX-E

Cooling capacity: 60 RT ~ 1000 RT (211 kW ~ 3517 kW)

Innovative vertical screw compressors provide better energy efficiency and longer lifespan compared to traditional horizontal compressors.

Efficient vertical compressors offer quieter operation and reduced mechanical friction losses.

The layout of vertical compressors provides more stable performance during low-load operation compared to traditional horizontal compressors.

Full-color touchscreen human-machine interface and advanced 2020i controller.

Full range AHRI certification and optionally available with ASME U-stamp certification. -

Read More

Variable Frequency Screw Chiller WCFX-V

Variable Frequency Screw Chiller WCFX-VVariable Frequency Screw Chiller WCFX-V

Cooling capacity: 130 RT ~ 750 RT (457 kW ~ 2638 kW)

Innovative vertical screw compressors provide better energy efficiency and longer lifespan compared to traditional horizontal compressors. When combined with frequency converter control, they offer the highest IPLV (COP) performance in the screw compressor industry.

Efficient vertical compressors offer quieter operation and reduced mechanical friction losses.

The layout of vertical compressors provides more stable performance during low-load operation compared to traditional horizontal compressors.

Full-color touchscreen human-machine interface and advanced 2020i controller.

Full range AHRI certification and optionally available with ASME U-stamp certification. -

Read More

Dual-Stage Centrifugal Chiller DCLC-D

Dual-Stage Centrifugal Chiller DCLC-DDual-Stage Centrifugal Chiller DCLC-D

Cooling capacity: 300 RT ~ 4000 RT (1055 kW ~ 14064 kW)

Dual-stage high-efficiency centrifugal impeller, with minimum power consumption as low as 0.521 kW/RT.

Utilizes patented high-strength aluminum alloy impellers for R134a refrigerant, increasing efficiency by 3% to 5%.

Semi-hermetic compressor design, eliminating oil leakage issues.

Refrigerant-cooled motor, no external cooling required.

Refrigerant-cooled refrigeration oil, no additional cooling water required.

Unique refrigerant throttling design to prevent low-load surging.

Optional installation of frequency converter.

Full-color touchscreen human-machine interface and full range AHRI certification, optionally available with ASME U-stamp certification. -

Read More

Dual-Compressor Variable Frequency Magnetic Levitation Centrifugal Chiller DCLC-M

Dual-Compressor Variable Frequency Magnetic Levitation Centrifugal Chiller DCLC-MDual-Compressor Variable Frequency Magnetic Levitation Centrifugal Chiller DCLC-M

Cooling capacity: 60 RT ~ 800 RT (211 kW ~ 2813 kW)

High-efficiency magnetic bearing.

Variable frequency drive dual-stage centrifugal compressor.

Oil-free operation.

Ultra-low noise and more compact footprint.

Full-color touchscreen human-machine interface and full range AHRI certification, optionally available with ASME U-stamp certification. -

Read More

Other DB products

Other DB productsOther DB products

In addition to the aforementioned products, our DB can also provide:

Air-cooled chiller units

Heat pumps

Ice storage systems

Integrated chiller plant control system (Chiller Plant Manager)

IoT Chiller Operation

Industrial low-temperature process chillers -

Read More

APV Plate Heat Exchanger

APV Plate Heat ExchangerAPV Plate Heat Exchanger

SPX offers advanced APV heat exchange solutions for fluid cooling, heating, condensing, and evaporation processes. Since the invention of the plate heat exchanger by APV in 1923, it has been a pioneer in applications such as stamping, forming, welding, sealing, and testing of plate materials.

In addition to providing industrial-grade plate heat exchangers with ASME U-Stamp certification, we also offer food hygiene grade plate heat exchangers certified by 3-A, FDA, and EHEDG.

• Various plate material options: SS304, SS316, SS317, 254SMO, 654SMO, 904L, C22, C276, C2000, Nickel Alloy 200/201, Ti Gr.1, Ti Gr.11/Gr.17.

• Maximum single plate area of 4.75m2 (approximately 4m high), maximum single interface diameter of φ500mm, maximum single processing flow rate of 4500 m3/hr.

• Laser-welded semi-welded plate heat exchangers are also available.

• With over 60 plate models, we can meet various heat exchange needs for liquid-liquid, evaporation, condensation, and gas-gas applications.

Advantages of APV plate heat exchanger technology:

1. Reliable plate interlocking structure and added suspension function.

2. Advanced Easyclip embedded gaskets require no glue for fixing, saving installation and cleaning time.

3. Efficient bypass zone design ensures uniform fluid distribution between channels, reducing resistance and improving heat transfer efficiency.

4. Double-layer leak prevention technology prevents fluid mixing at corner holes and makes it easier to identify leak positions.

5. Combination of soft and hard plate channel assembly allows for flexibility in design with different types of corrugated plates.

6. Various corrugated plate designs provide greater design flexibility.

Further information is available on the official SPX FLOW website:

Industrial Plate Heat Exchangers、Sanitary Plate Heat Exchangers