Seital Centrifuge

DETAIL

Typical uses of centrifuges include:

• Clarification of liquids

• Separation of liquids

• Dehydration separation of suspensions and biomass

• Recovery of solid materials

• Extraction of valuable products

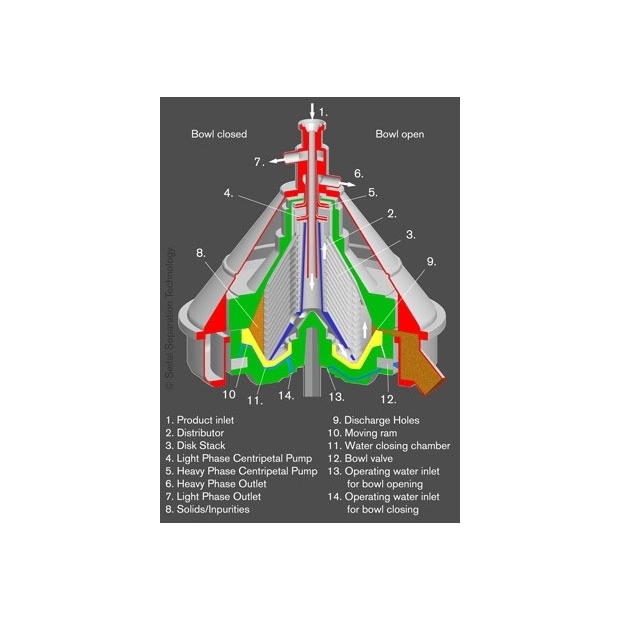

SPX FLOW's Seital centrifuges offer a variety of centrifuges for liquid-liquid, liquid-solid, or liquid-liquid-solid separation. Our centrifuges feature a self-cleaning design suitable for various high-demand processes, with processing capacities ranging from 500 l/h to 10,000 l/h (solids-retaining type) and 1,000 l/h to 70,000 l/h (self-cleaning type). All models are CIP capable. Utilize ultra-high centrifugal force to recover fine particles (0.5-500 mm) or separate clarified liquids.

Seven Advantages of SPX FLOW Seital Centrifuges:

• Short installation time - Modular equipment, no civil foundation, electrical or fluid testing required on-site.

• High performance - Innovative design developed using advanced software modeling tools, achieving precise mechanical and fluid analysis.

• High product quality - Use of mechanical seals to reduce oxidation risks, minimizing oxygen pick-up and CO2 loss.

• High uptime - Real-time operational diagnostics through remote monitoring, allowing for functional checks by technical personnel.

• Effective process control - Customized process adjustment settings.

• Lower maintenance requirements - Improved mechanical component reliability through high dynamic stability.

• Lower investment - Wide range of models and flexible accessory options.

Further information is available on the official SPX FLOW website:Seital Separation