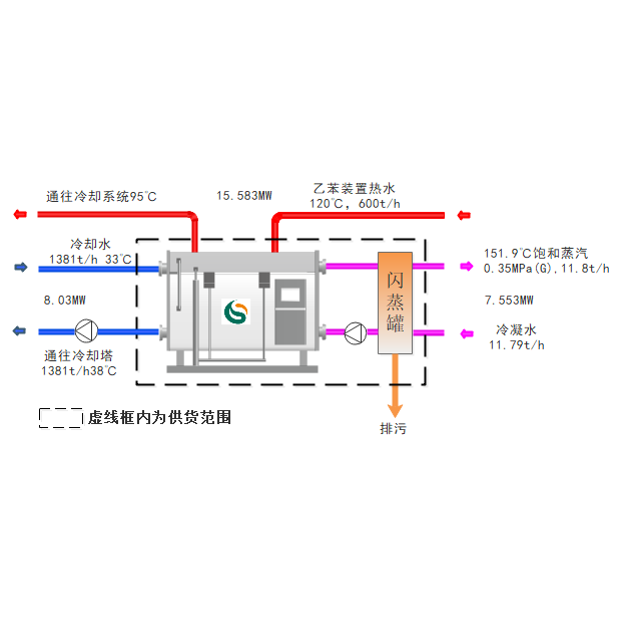

Lithium bromide absorption heat pumps, which operate based on the same principles as absorption chillers, have recently gained attention as an effective solution for large-scale heat recovery projects—particularly in upgrading low-grade waste heat into usable thermal energy. These systems are especially advantageous in industrial applications where maximizing energy efficiency is critical.

Absorption heat pumps are typically classified into two types:

Type I – Heat Booster (Heat Addition): Driving heat temperature > Output heat temperature

(Heat quantity increase / Waste heat upgrading)

Also known as a heat-boosting absorption heat pump, this system primarily utilizes a high-temperature heat source (such as steam) to drive the cycle, transforming low-temperature waste heat into a large amount of usable medium-temperature heat.

-

Uses a small amount of high-grade thermal energy (e.g., steam below 8 barg)

-

Elevates low-grade waste heat (around 50–70 °C) to a useful range (70–110 °C)

-

Ideal for large-scale industrial heating or district heating networks

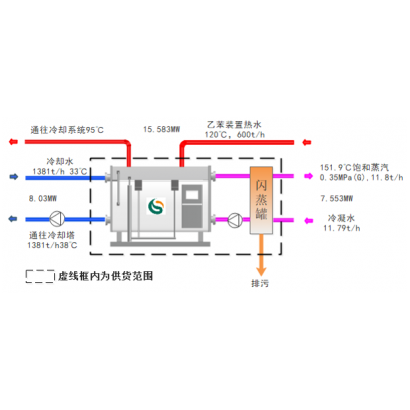

Heat balance example:

100% high-temperature driving heat + 80% low-temperature waste heat

→ yields approximately 180% useful medium-temperature heat output

Primary benefits:

-

Significantly reduces steam consumption for heating

-

Additional benefit: lowers cooling water temperature

Type II – Temperature Lifting (Exergy Upgrade): Driving heat temperature < Output heat temperature

(Temperature lift / Waste heat utilization)

Also known as a temperature-lifting absorption heat pump, this system utilizes medium-temperature waste heat and upgrades its thermal quality, allowing for reuse at higher temperature levels.

-

Uses medium-temperature waste heat (80–100 °C) as the driving source

-

Releases part of the heat to the environment via cooling water

-

Delivers the remainder as higher-temperature output heat

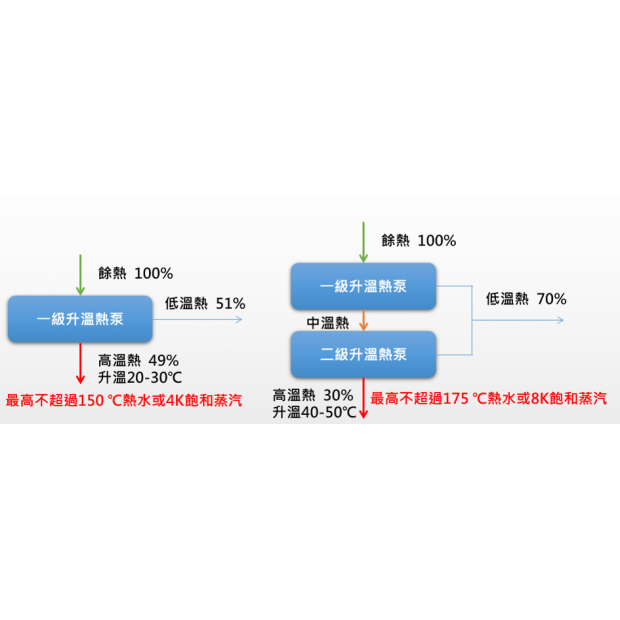

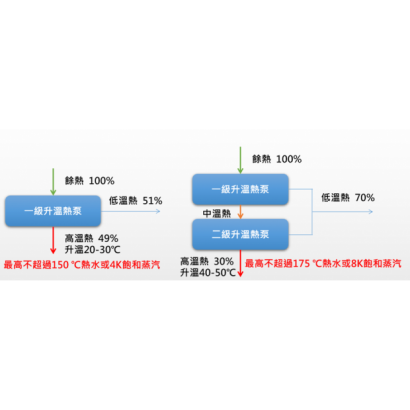

Two-stage operation examples:

-

Stage 1 Output Temperature: approx. 110–150 °C

-

Stage 2 Output Temperature: up to approx. 170 °C

Heat balance:

-

Stage 1: 100% input – 50% lost to cooling = 50% high-temp useful heat

-

Stage 2: 100% input – 70% lost = 30% high-temp useful heat

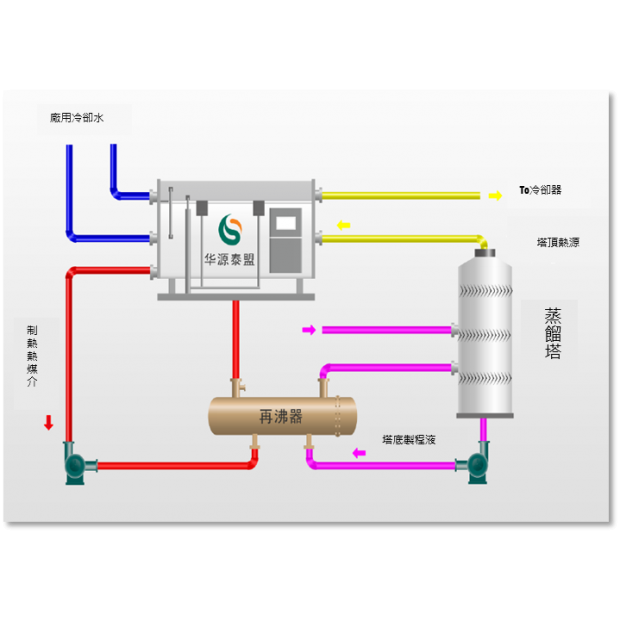

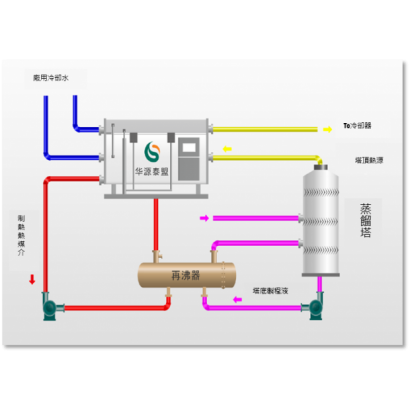

Common applications:

Widely used in chemical plants for top-column heat recovery in distillation systems. It can replace traditional top condensers while simultaneously supplying steam for other processes.