Shuangliang Group

-

Read More

Electrode Boilers and Heat Storage

Electrode Boilers and Heat StorageElectrode Boilers and Heat Storage

Electrode Boiler with Thermal Energy Storage

Shuangliang’s electrode boiler combined with thermal energy storage technology is especially suitable for applications with fixed cycles or intermittent demands for steam or thermal energy.

The system adopts the following technical approach:

The electrode boiler generates steam using electricity, which can come from solar panels (green power) or the power grid.

The thermal energy storage system stores heat in the form of high-pressure hot water inside an insulated tank. This stored energy can be released when steam or heat is needed.

Key Advantages:

Utilizes low-cost electricity (e.g., off-peak night-time electricity or surplus renewable energy) for heat generation.

Stores energy during low-demand periods and releases steam or thermal energy during peak demand, maximizing energy efficiency and cost savings. -

Read More

Air Cooling & Drift Elimination Towers

Air Cooling & Drift Elimination TowersAir Cooling & Drift Elimination Towers

Advanced Industrial Cooling Solutions from Shuangliang Group

With strong R&D and manufacturing capabilities, Shuangliang Group offers a full range of industrial circulating water cooling solutions, including:

High-Efficiency Air Coolers for Circulating Water

✔ Compared with traditional horizontal aluminum finned air coolers, our solutions offer significant advantages in cost, weight, air resistance (energy consumption), ease of cleaning and maintenance, corrosion resistance, and space efficiency.

Water-Saving and Anti-Drift Cooling Towers

✔ Separated water-saving anti-drift cooling towers

✔ Horizontally arranged dry-wet separation towers

✔ Vertically arranged dry-wet separation towers

✔ L-shaped hybrid dry-wet closed cooling towers

✔ Overlapping hybrid dry-wet cooling towers

✔ Modular hybrid dry-wet cooling towers

✔ Natural draft cooling towers

Water-Saving Retrofit Solutions for Existing Open Cooling Towers

✔ Utilizing our proprietary technologies and products, we offer retrofit solutions for open-type cooling towers to enhance water-saving and anti-drift (white smoke elimination) performance.

✔ Achievable results include:

Peak season water saving

Year-round anti-drift and white plume elimination

Variable frequency fan control

Energy-saving fan operation

Our Core Cooling Technology: Proprietary High-Efficiency Fin Tube Bundles

All our cooling products are built upon Shuangliang’s independently developed and manufactured high-efficiency finned tube bundles, with the following technical advantages:

High-efficiency heat exchange components

Low air resistance and reduced fan power consumption

Minimal heat exchange efficiency degradation over time

Strong corrosion resistance

Easy and convenient tube cleaning

100% air-tightness tested tube bundles

Intelligent control systems for maximum energy and water savings -

Read More

Shuangliang Air Cooling

Shuangliang Air CoolingShuangliang Air Cooling

Our company, in collaboration with Shuangliang, pioneered the promotion of Flat Tube ACC (Air Cooled Condenser) in Taiwan. Clyde Bergemann, established in 2014 in cooperation with Shuangliang, focuses on the development of air-cooling technology.

Shuangliang's air cooling technology boasts complete independent intellectual property rights, replacing traditional water cooling with air cooling, applicable in power generation units and process cooling, with a water saving rate of over 85%. (For example, in a 1 million kilowatt thermal power plant, it can save at least 100 million tons of water per year, equivalent to the annual water consumption of 500,000 urban residents.)

Research and development achievements include air-cooled anti-freezing test research, million-unit seismic test research, and wind engineering research on intercooler towers, leading the industry's technological advancement.

Our company provides industry-leading Flat Tube ACC products, based on robust research and manufacturing capabilities.

Three major testing facilities ensure overall product performance:

Bundle performance test device, used to obtain optimized flat tube designs and more accurate heat transfer data.

Shuangliang has set up a 1:1 1000MW level ACC prototype in the park, which is the industry's only large-scale hot-state air cooling test system.

The industry's unique air-cooling test laboratory (-25 ℃ to 40 ℃) and environmental test facility.

Nine test researches thoroughly analyze the performance of heat exchange components:

Test research on heat exchange performance of heat exchange components.

Test research on air-side resistance characteristics of heat exchange components.

Test research on steam-side resistance characteristics of heat exchange component tubes.

Aluminum fin atmospheric corrosion performance test research.

Weld seam and corrosion resistance test of base tube.

Bundle fouling performance test.

Bundle flushing test.

Anti-freezing test research of bundle.

Air-cooled bundle fatigue test. -

Read More

Heat Exchange Equipment for Power Plants

Heat Exchange Equipment for Power PlantsHeat Exchange Equipment for Power Plants

During the power generation process in power plants, steam power cycles (Rankine cycles) are utilized, which include processes such as constant pressure heat absorption, isentropic expansion, constant pressure heat rejection, and isentropic compression. Additionally, reheating cycles and regenerative cycles are often incorporated.

In the power generation cycle, our company collaborates with Shuangliang Group to provide customers with all auxiliary equipment for power plants besides turbines and boilers. These include:

Surface Condenser

Air Cooled Condenser

LP Feed Water Heater

HP Feed Water Heater

Deaerator

Air Ejector

Water Ring Vacuum Pump

Gland Steam Condenser -

Read More

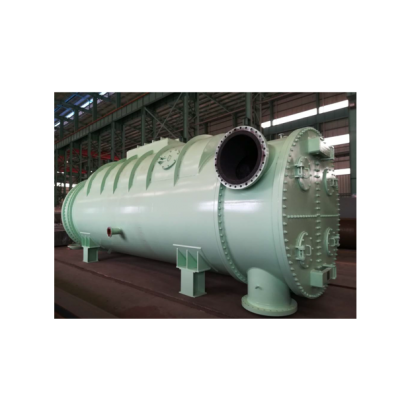

Shuangliang High Efficiency Heat Exchanger

Shuangliang High Efficiency Heat ExchangerShuangliang High Efficiency Heat Exchanger

Shuangliang is capable of designing and providing various advanced and efficient heat exchanger products, and is the only equipment manufacturer in the industry that provides fluid analysis and structural optimization analysis, capable of providing customers with front-end process design and structural simulation analysis.

Our technical capabilities include:

G-type finned tube: Reasonable tube arrangement, low shell-side pressure drop, saving energy by 20%. Withstands high temperatures up to 400℃.

Double pipe plate structure: The double pipe plate structure effectively prevents contact between tube-side steam and shell-side nitrogen.

Single pipe plate deep hole structure: Single plate + deep hole safety ring plate structure.

Stress analysis: Overall structural stress analysis, higher design reliability.

Deep hole welding: Fatigue resistance, best sealing butt welding method, using imported French Polysoude welding machine with "steady flow circuit power supply, walking accuracy compensation" for one-time welding.

Large bundle assembly: Small diameter, thin wall, super long (27 meters long heat exchange tube) heat exchange tube surface protection assembly, non-traditional center positioning butt welding for tube holes and heat exchange tubes.

Comprehensive helium leak detection: Improved helium leak detection fixtures, helium leak detection using suction gun method, meeting European and Japanese standards requirements. -

Read More

Shuangliang Seawater Desalination

Shuangliang Seawater DesalinationShuangliang Seawater Desalination

Low Temperature-Multi Effect Distillation (MED) for seawater desalination refers to a desalination technology where the highest brine temperature (TBT) does not exceed 70°C, characterized by a series of horizontal (or vertical) tube falling film evaporators connected in series and divided into several effect groups. A certain amount of steam is inputted through multiple evaporation and condensation cycles, resulting in distilled water multiple times the amount of heating steam.

Technical Features:

Adaptability to different high and low-grade waste heat situations, improving overall efficiency.

Low operating temperature to avoid or reduce equipment corrosion and scaling.

No need for complex pretreatment of seawater, suitable for various changes in seawater conditions.

Stable and reliable device operation, with low maintenance and repair requirements, and low cost.

Strong load adaptability, with an adjustment range of 40% to 110%.

High product water quality with a salt content lower than 5mg/L.

Application Scenarios:

Suitable for large and medium-sized seawater desalination plants utilizing high and low-grade steam provided by power plants and chemical plants, especially suitable for utilizing low-grade waste heat.

The product water has extremely high purity and can be used as boiler makeup water, process water in production processes, or for large-scale municipal drinking water supply.