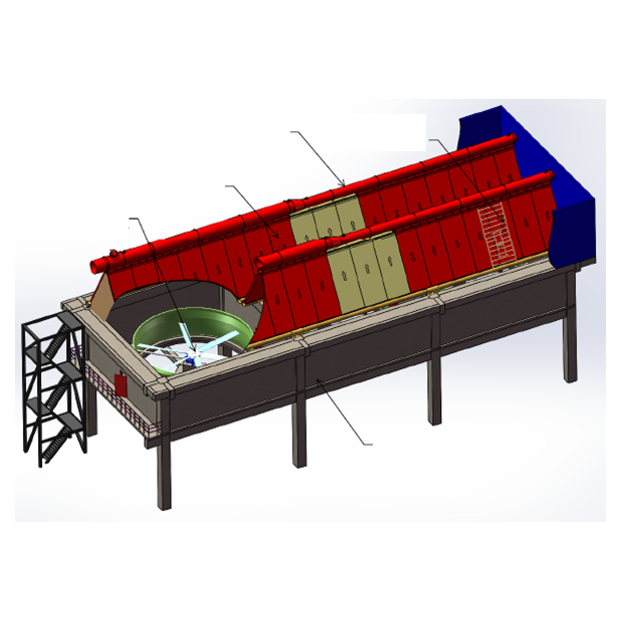

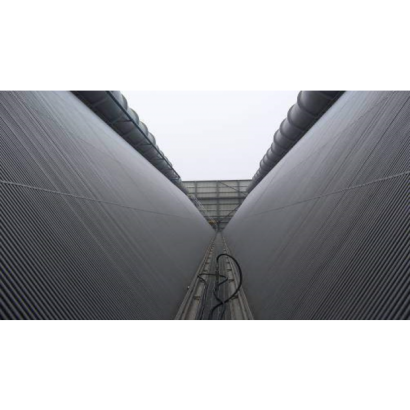

Air Cooled Condenser (ACC)

DETAIL

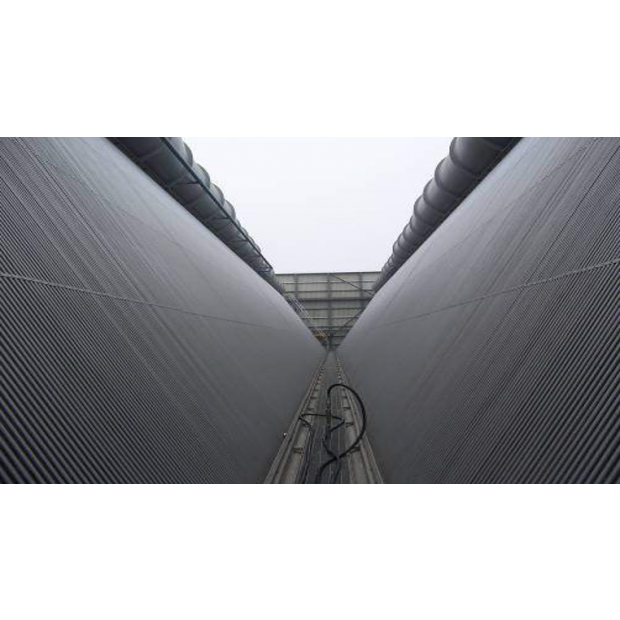

Advantages of air cooling include:

1. Easy access to air.

2. Air-cooled systems are easy to design, operate, and maintain, offering high reliability.

3. Unlike water, which is corrosive, air does not corrode equipment, leading to lower cleaning and maintenance costs compared to water-cooled systems.

4. Maintenance costs for air-cooled systems are only 20% to 30% of those for water-cooled systems.

Although air cooling requires fan power consumption, water-cooled systems also consume significant power for water circulation pumps and incur expensive water treatment costs, resulting in higher operating expenses.

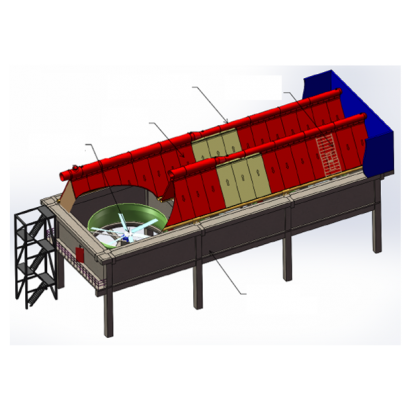

Through collaboration with Shuangliang Group, we provide customers with the highest quality ACC products globally.

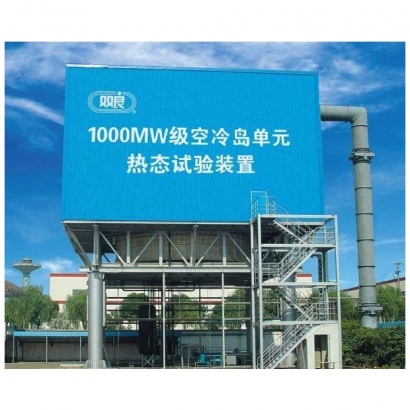

Our technical features include three major testing devices to ensure comprehensive performance testing before product delivery:

1. Bundle Performance Test Device—acquires actual finned tube heat transfer coefficients to optimize heat transfer performance.

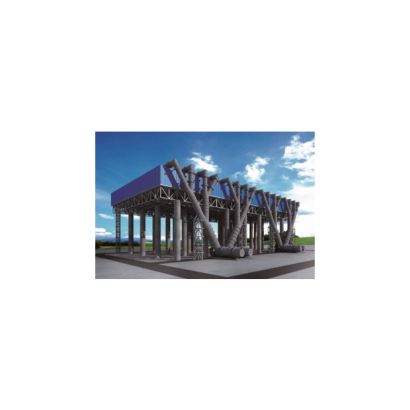

2. Industry-exclusive large-scale dynamic air-cooled test system—installed within Shuangliang's factory, simulating a 1000MW unit ACC to compare test performance with actual units.

3. Industry-exclusive air-cooled laboratory (-25 ℃ to 40 ℃) and environmental test equipment—tests actual heat transfer performance at various temperatures.

Nine testing and research studies thoroughly analyzing heat transfer performance within the bundle throughout its lifespan:

1. Bundle heat transfer performance testing and research.

2. Bundle air-side resistance characteristic testing and research.

3. Bundle steam-side resistance characteristic testing and research.

4. Aluminum fin atmospheric corrosion performance testing and research.

5. Base tube welding and corrosion resistance testing.

6. Bundle fouling performance testing.

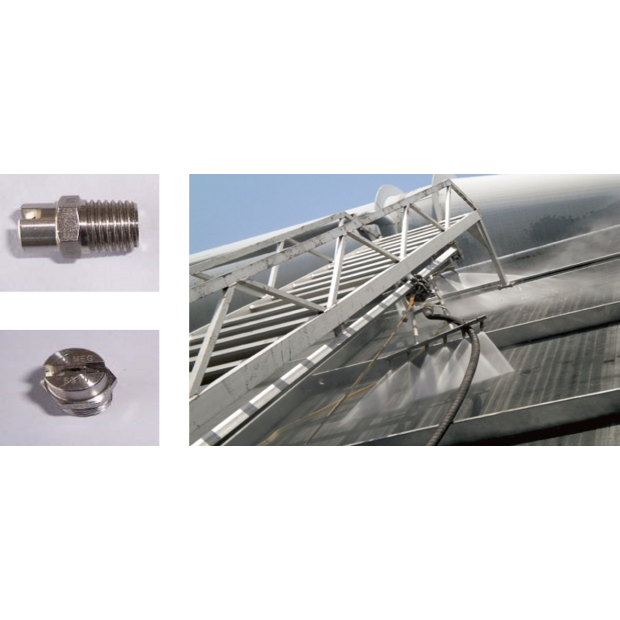

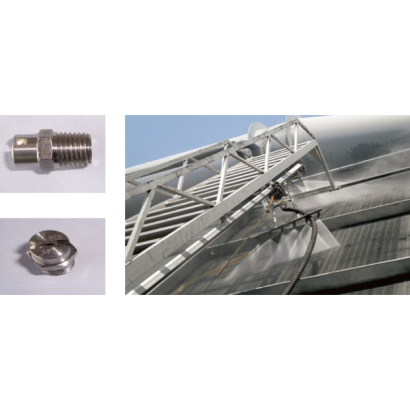

7. Bundle flushing testing.

8. Bundle anti-freezing testing and research.

9. Air-cooled bundle fatigue testing.