All Project

-

Read More

Ejector

EjectorEjector

An ejector is a static device that uses a high-pressure driving fluid to entrain and transport a low-pressure fluid, without any moving parts. Its simple structure and low maintenance make it widely used in various industrial processes, including transport and mixing, vacuum generation, and thermal energy recovery.

Main Components:

Nozzle: Accelerates the high-pressure driving fluid (e.g., steam or gas) into a high-velocity jet.

Mixing Chamber: The high-speed jet entrains the low-pressure suction fluid, and kinetic energy is transferred to the mixture.

Diffuser: The mixed flow decelerates, converting kinetic energy into pressure, thus increasing outlet pressure.

Key Advantages:

Simple Design: No moving parts, low failure rate, minimal maintenance.

Versatile Media Handling: Suitable for gases, liquids, steam, and even particle-laden fluids.

Corrosion Resistance: Material options available for corrosive media.

Oil-Free Operation: Ideal for clean industries like food and pharmaceuticals.

Leak-Free: No rotating elements, reducing leakage risk.

Typical Applications:

Steam Jet Air Ejectors in power plants for removing non-condensable gases.

Steam heating and mixing in large storage tanks.

Vacuum distillation systems in chemical plants for maintaining vacuum and removing by-products.

Corrosive gas handling in process industries.

Blast furnace gas transport to reheating furnaces in steel plants.

Vacuum degassing of molten steel.

Freeze-drying and concentration processes. -

Read More

Lithium Bromide Absorption Heat Pump

Lithium Bromide Absorption Heat PumpLithium Bromide Absorption Heat Pump

Lithium bromide absorption heat pumps, which operate based on the same principles as absorption chillers, have recently gained attention as an effective solution for large-scale heat recovery projects—particularly in upgrading low-grade waste heat into usable thermal energy. These systems are especially advantageous in industrial applications where maximizing energy efficiency is critical.

Absorption heat pumps are typically classified into two types:

Type I – Heat Booster (Heat Addition): Driving heat temperature > Output heat temperature

(Heat quantity increase / Waste heat upgrading)

Also known as a heat-boosting absorption heat pump, this system primarily utilizes a high-temperature heat source (such as steam) to drive the cycle, transforming low-temperature waste heat into a large amount of usable medium-temperature heat.

Uses a small amount of high-grade thermal energy (e.g., steam below 8 barg)

Elevates low-grade waste heat (around 50–70 °C) to a useful range (70–110 °C)

Ideal for large-scale industrial heating or district heating networks

Heat balance example:

100% high-temperature driving heat + 80% low-temperature waste heat

→ yields approximately 180% useful medium-temperature heat output

Primary benefits:

Significantly reduces steam consumption for heating

Additional benefit: lowers cooling water temperature

Type II – Temperature Lifting (Exergy Upgrade): Driving heat temperature < Output heat temperature

(Temperature lift / Waste heat utilization)

Also known as a temperature-lifting absorption heat pump, this system utilizes medium-temperature waste heat and upgrades its thermal quality, allowing for reuse at higher temperature levels.

Uses medium-temperature waste heat (80–100 °C) as the driving source

Releases part of the heat to the environment via cooling water

Delivers the remainder as higher-temperature output heat

Two-stage operation examples:

Stage 1 Output Temperature: approx. 110–150 °C

Stage 2 Output Temperature: up to approx. 170 °C

Heat balance:

Stage 1: 100% input – 50% lost to cooling = 50% high-temp useful heat

Stage 2: 100% input – 70% lost = 30% high-temp useful heat

Common applications:

Widely used in chemical plants for top-column heat recovery in distillation systems. It can replace traditional top condensers while simultaneously supplying steam for other processes. -

Read More

Lithium Bromide Absorption Chiller

Lithium Bromide Absorption ChillerLithium Bromide Absorption Chiller

Main Heat Exchange Components of an Absorption Chiller:

Evaporator

Condenser

Generator

Absorber

Refrigerant (Water) Cycle:

Water vapor and concentrated lithium bromide solution are separated in the generator → Vapor condenses into water in the condenser → Throttled to the evaporator for cooling → Absorbed by lithium bromide in the absorber to form a diluted solution → Returned to the generator.

Lithium Bromide Circulation (Replaces Compressor Function):

Concentrated solution from the generator → Pressure reduced via throttling → Absorbs water vapor in the absorber to form a diluted solution → Pumped back to the generator after pressurization.

Advantages:

Simple structure with minimal mechanical components for stable, low-vibration operation.

Easy operation with wide cooling capacity modulation from 10% to 100%.

Compatible with low-grade heat sources such as waste heat, hot water, or steam.

Driven by thermal energy; power consumption is only 5% of equivalent electric chillers.

High cooling efficiency under stable heat supply and suitable for automation.

Limitations:

Lithium bromide solution is corrosive to carbon steel; regular maintenance is required.

Operates under vacuum; requires excellent sealing. Air leakage may lead to performance degradation.

High cooling water demand.

Main Models:

Single-effect hot water type: 30 RT to 3000 RT (also available in two-stage configuration)

Single-effect / Double-effect steam type: 50 RT to 1500 RT

Double-effect flue gas type: 100 RT to 1500 RT

-

Read More

Retubing On-Site Services

Retubing On-Site ServicesRetubing On-Site Services

With over 30 years of extensive experience, Taiwan Heat Transfer provides high-quality and rapid on-site retubing services for major power plants, steel mills, and chemical plants across Taiwan. We specialize in maintenance and replacement projects for various heat exchangers, power plant condensers, feedwater heaters, and air preheaters, consistently adhering to high-quality and cost-effective standards.

Leveraging the richest on-site retubing experience in Taiwan and our self-developed specialized equipment, we guarantee the most professional, punctual, and low-risk retubing services for our clients.

When to Consider On-Site Retubing:

To extend the service life of heat exchangers

When localized corrosion occurs and full tube replacement is not desired

When the entire bundle cannot be removed or replaced

When plugging exceeds 5%, causing a significant drop in heat transfer area

When material replacement is required due to corrosion -

Read More

Pilot Plants & Turnkey Project Solutions

Pilot Plants & Turnkey Project SolutionsPilot Plants & Turnkey Project Solutions

We offer comprehensive solutions for pilot plants and small to mid-scale turnkey projects, delivering full-scope services including process design, in-house manufacturing, modular fabrication, on-site installation, and commissioning with handover. These modular systems are ideal for R&D, pilot testing, pre-production, or compact industrial applications.

Our professional services include:

Pilot Plant Design, Manufacturing & Fabrication

Tailored for R&D, technology validation, and pilot-scale production

Custom skid systems, test modules, and modular platforms

Flexible and scalable systems designed for future expansion

Process Optimization & Debottlenecking

Evaluation of existing systems and process bottlenecks

Reconfiguration of piping, layout, and controls for improved efficiency

Solutions for fouling, corrosion, and performance enhancement

Flexible integration with existing equipment or modules for new installations

Heat Recovery Systems

Design and integration of thermal energy recovery

Reduce consumption of steam, chilled water, compressed air, and electricity

Enhance energy efficiency and carbon footprint control

Engineering Execution & Construction Capabilities:

In-House Manufacturing and Pre-Assembly

100% in-house fabrication of equipment and modules

Factory Acceptance Testing (FAT) conducted before delivery

Pre-assembled systems to minimize on-site uncertainties

Provision of technical services related to factory inspection

On-site Execution and Project Management

Piping installation

Lifting operations and equipment positioning

Thermal insulation and refrigeration

Steel structure and foundation works

Control system integration

Instrumentation and electrical wiring

Quality and Safety Management

Engineering documentation and quality inspections per ITP

Implementation of safety plans, Job Safety Analysis (JSA), and SOPs

Proven track record in petrochemical, chemical, and energy sectors

Our Key Strengths:

Cross-disciplinary integration: from equipment manufacturing → process design → on-site execution → control systems → commissioning and handover

Expertise in both greenfield projects and system upgrades/retrofits

Proficiency in unit operations: heat exchange, fluid handling, gas-liquid separation, heating, cooling, cryogenic refrigeration, and steam processing

Ideal partner for R&D teams, engineering firms, plant optimization initiatives, and ESCO energy-saving projects -

Read More

Modular Process Skid Systems

Modular Process Skid SystemsModular Process Skid Systems

We are a specialized manufacturer of heat exchangers and process equipment, certified for pressure vessel fabrication and equipped with in-house production capabilities. We provide one-stop modular process skid solutions tailored for diverse industrial applications.

Key Advantages:

Certified Pressure Vessel Manufacturer: We are qualified to manufacture and fabricate pressure vessels meeting ASME, CNS, and other standards. Our facility produces heat exchangers, reactors, storage tanks, and related equipment for chemical, energy, food, and environmental industries.

Modular Process Skid Design & Integration: Complete design services cover modular skid units, including PFD/P&ID development, 3D modeling, piping layout, and structural integration. Modularization shortens on-site construction time and enhances safety. Systems are fully assembled and tested in-house to ensure consistent quality and timely delivery.

Thermal & Process Engineering: Expertise in thermal and fluid engineering allows optimization of heat transfer and process control for maximum efficiency.

Automation & Electrical Integration:Services include PLC programming, instrumentation selection, power distribution, and HMI integration, with options for smart control and remote monitoring.

On-Site Installation & Commissioning: Skids are delivered fully assembled, requiring only utility connections, significantly reducing installation time and labor. Field support, commissioning, and operator training are also provided.

Committed to the core principles of quality, efficiency, and flexibility, we strive to be your most trusted partner for modular equipment and thermal process systems. Whether it’s a new project, system upgrade, or customized solution, we welcome the opportunity to collaborate with you.

In addition, we have recently expanded our offerings to include modular CO₂ capture solutions. These systems come in various capacities with comprehensive process design support to meet diverse needs.

Please feel free to contact us for further information or consultation.

-

Read More

Shell and Tube Heat Exchanger

Shell and Tube Heat ExchangerShell and Tube Heat Exchanger

The shell and tube heat exchanger is a type of heat exchanger known for its simple structure and easy maintenance. It is capable of withstanding high pressures and finds wide applications in various industries including chemical processes, power plants, refrigeration systems, and more.

Typically, a shell and tube heat exchanger consists of four main components: the tube bundle, shell, channel, and shell cover. These components are named according to the classification standards of TEMA (Tubular Exchanger Manufacturers Association).

For detailed information, please refer to the technical data sharing section on our company website.

Our Key Features:

One of the most widely used types of heat exchangers in industrial applications

Designed in accordance with TEMA standards

Certified with ASME U Stamp and CNS pressure vessel regulations

Available in a wide range of materials, including carbon steel (CS), stainless steel (SS), titanium (Ti), duplex stainless steel, nickel (Ni), Hastelloy, Inconel, copper (Cu), and more

Available with food-grade hygienic design upon request -

Read More

Fin Tube Heat Exchanger

Fin Tube Heat ExchangerFin Tube Heat Exchanger

Finned tube heat exchangers have a structure similar to conventional shell-and-tube heat exchangers. However, instead of smooth tubes, finned tubes are used as the heat transfer surface. Due to enhanced heat transfer and compact structure, they are also known as compact heat exchangers. The primary purpose of adding fins is to increase the heat exchange surface area and promote heat exchange efficiency.

To increase the heating surface area, it can be achieved by increasing either the outer or inner surface. The additional area is referred to as the Secondary Area. Currently, there are various types of finned tubes used in the industry, with designs primarily focusing on external fins. External fins can be classified into several types: low finned tubes, high finned tubes, and continuous finned tubes. Selection of finned tubes depends on different operating conditions, and there are numerous options for the combination of fins and smooth tubes. Optimal selection can be made based on factors such as the type of fluid, operating temperature, and corrosiveness.

Taiwan Heat Transfer can provide various types of finned tube heat exchangers according to your specific requirements! -

Read More

Power Plant Heat Exchangers and Deaerators

Power Plant Heat Exchangers and DeaeratorsPower Plant Heat Exchangers and Deaerators

Regardless of whether it's a nuclear power plant, thermal power plant, cogeneration plant, etc., as long as it utilizes a steam turbine for power generation, although the heat sources may vary, the principle of power generation remains the same. It involves utilizing a steam turbine for power generation, with the thermal cycle referred to as the steam power cycle or Rankine Cycle.

In the Rankine cycle of steam, feed water absorbs heat in the boiler (or steam generator) to produce steam, which is then sent through pipes to the turbine to expand and perform work, driving the generator for electricity generation. After performing work, the low-pressure exhausted steam is sent to the condenser for cooling, where it condenses into liquid form. It is then pumped back to the boiler through feed water pumps, passing through either high-pressure or low-pressure feed water heaters for reheating and through deaerators for thermal deaeration, thus forming a closed cycle.

Our Scope of Supply

Our company specializes in the design and manufacturing of a wide range of auxiliary heat exchange equipment used in power generation systems (excluding boilers), including:

Surface Condensers

Feedwater Heaters (Low-Pressure & High-Pressure)

Deaerators

Air Preheaters

Gland Steam Condensers

Air Ejectors

Condenser:

In the steam power cycle, the condenser primarily functions to:

1. Release heat at the cold end and recover condensed exhausted steam to feed water.

2. Remove non-condensable gases and dissolved oxygen from water to prevent system corrosion.

3. Lower back pressure, maintain vacuum, increase turbine effective enthalpy drop, thereby enhancing cycle efficiency.

Condensers are classified into water-cooled (Surface Condenser) and air-cooled (Air Cooled Condenser), both of which our company can provide.

Vacuum level of the condenser is one of the main performance indicators. Our company can also provide vacuum equipment for the condenser, such as Air Ejectors and water ring vacuum pumps.

Feed Water Heater:

Feed Water Heater (FWH), its function is to heat feed water (boiler water) using extracted steam from the turbine, thus increasing the overall cycle efficiency, also known as regenerative heating. Feed water heaters include high-pressure heaters (HP) and low-pressure heaters (LP). Generally, the low-pressure heater (with lower tube-side pressure) is located between the condenser and deaerator, while the high-pressure heater (with higher tube-side pressure) is located after the feed water pump.

The advantages of using feed water heaters in power plants are as follows:

1. Improved thermal efficiency: Utilizing extracted steam for feed water heating reduces steam flow to the condenser, minimizing heat sink losses, thus enhancing cycle thermal efficiency.

2. For boilers, the increased feed water temperature reduces the boiler heat load, leading to a decrease in furnace heat exchange area, thereby saving energy and steel usage.

3. By having intermediate extraction steam, the steam flow to the last stages of the turbine is reduced, which in turn reduces the flow area of the last-stage turbine blades, addressing challenges in the design and manufacturing of turbine last-stage blades.

4. With reduced steam flow into the condenser, the heat load of the condenser decreases, reducing heat exchange area, thus saving investment costs and minimizing heat discharge to the environment.

Deaerator:

The deaerator is designed to remove dissolved oxygen from boiler feed water to protect the boiler from oxygen corrosion. Thermal deaeration is one of the primary methods for preventing corrosion in power plant boilers or industrial boilers.

In a deaerator, thermal deaeration is primarily used because the amount of gas dissolved in water is directly proportional to the partial pressure of the gas above the water surface (Henry's law). The principle is to use steam to heat feed water, increasing the water temperature and gradually increasing the partial pressure of steam above the water surface, while the partial pressure of dissolved gases gradually decreases.

As a result, gases dissolved in water continuously escape. When water is heated to the boiling temperature corresponding to the respective pressure, the water surface is entirely covered with water vapor, and the partial pressure of dissolved gases is zero. At this point, water no longer has the ability to dissolve gases, including oxygen. The effectiveness of deaeration depends on whether the feed water is heated to the boiling temperature corresponding to the respective pressure and the rate of gas removal, which is closely related to the contact surface area between water and steam. -

Read More

Air Cooled Condenser (ACC)

Air Cooled Condenser (ACC)Air Cooled Condenser (ACC)

The Air Cooled Condenser (ACC) is a critical component in power generation cycles. In the steam power cycle, the ACC serves as a cooling source. The heat from turbine exhaust steam is transferred to the ambient air through the ACC, resulting in condensation and negative pressure, thereby facilitating a continuous flow of fresh steam into the turbine. The relationship between negative pressure and turbine efficiency is significant, thus the efficiency of the ACC directly impacts overall power generation.

Advantages of air cooling include:

1. Easy access to air.

2. Air-cooled systems are easy to design, operate, and maintain, offering high reliability.

3. Unlike water, which is corrosive, air does not corrode equipment, leading to lower cleaning and maintenance costs compared to water-cooled systems.

4. Maintenance costs for air-cooled systems are only 20% to 30% of those for water-cooled systems.

Although air cooling requires fan power consumption, water-cooled systems also consume significant power for water circulation pumps and incur expensive water treatment costs, resulting in higher operating expenses.

Through collaboration with Shuangliang Group, we provide customers with the highest quality ACC products globally.

Our technical features include three major testing devices to ensure comprehensive performance testing before product delivery:

1. Bundle Performance Test Device—acquires actual finned tube heat transfer coefficients to optimize heat transfer performance.

2. Industry-exclusive large-scale dynamic air-cooled test system—installed within Shuangliang's factory, simulating a 1000MW unit ACC to compare test performance with actual units.

3. Industry-exclusive air-cooled laboratory (-25 ℃ to 40 ℃) and environmental test equipment—tests actual heat transfer performance at various temperatures.

Nine testing and research studies thoroughly analyzing heat transfer performance within the bundle throughout its lifespan:

1. Bundle heat transfer performance testing and research.

2. Bundle air-side resistance characteristic testing and research.

3. Bundle steam-side resistance characteristic testing and research.

4. Aluminum fin atmospheric corrosion performance testing and research.

5. Base tube welding and corrosion resistance testing.

6. Bundle fouling performance testing.

7. Bundle flushing testing.

8. Bundle anti-freezing testing and research.

9. Air-cooled bundle fatigue testing.

-

Read More

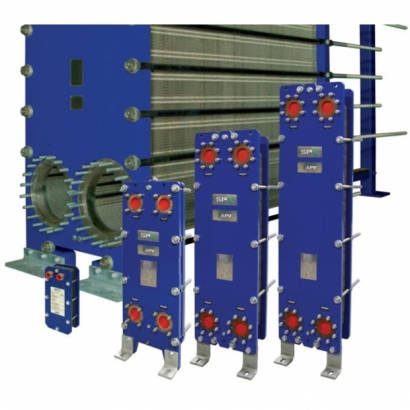

Plate Heat Exchanger

Plate Heat ExchangerPlate Heat Exchanger

Advantages of Plate Heat Exchangers (PHE):

1. Variable Heat Transfer Area with Load: The number of heat transfer plates can be adjusted within the same frame according to the load.

2. Compact Size: The volume is approximately 1/4 to 1/5 of that of shell and tube heat exchangers for the same heat transfer capacity.

3. Lightweight: The weight is approximately half that of shell and tube heat exchangers for the same heat transfer capacity.

4. Cost-effective: Particularly advantageous for counter-current flow, especially in low temperature differential heat transfer scenarios.

5. High Heat Transfer Efficiency: Internal flow fields are typically highly turbulent, resulting in a fouling resistance of only 10% to 25% compared to shell and tube heat exchangers.

Disadvantages of Plate Heat Exchangers (PHE):

1. Poor Pressure Resistance.

2. Risk of Gasket Leakage.

3. Narrow Passages Prone to Blockage.

Taiwan Heat Transfer can provide:

• Plate heat exchangers in various materials, including:

316 Stainless Steel, 317L Stainless Steel, 254SMO, AL6XN, Hastelloy, Incoloy, Titanium

• Plate heat exchangers with a variety of certifications, including:

ASME Pressure Vessel Certification, 3A/EHEDG Hygienic Certification for Food Applications,

AHRI Certification for HVAC and Refrigeration, FDA Compliance -

Read More

Gas-to-Gas Heat Exchanger

Gas-to-Gas Heat ExchangerGas-to-Gas Heat Exchanger

Gas-to-gas heat exchangers are commonly utilized for air preheating and flue gas heat recovery applications, where the pressures on both the hot and cold sides are generally not high. During the design process, special attention is required for:

1. Pressure drop issues.

2. Ash accumulation and fouling problems.

3. Flue gas corrosion concerns.

4. Thermal stress issues.

Taiwan Heat Transfer offers a wide range of custom-designed gas-to-gas heat exchangers and air preheaters:

✔ Suitable for flue gas heat recovery in boilers, RTOs, TOs, and incinerators

✔ Available with refractory lining, soot blowers, corrosion-resistant materials, and other optional accessories

✔ On-site installation and system integration services available