SPX Flow

-

Read More

SPX FLOW Genuine Spare Parts & Services

SPX FLOW Genuine Spare Parts & ServicesSPX FLOW Genuine Spare Parts & Services

We supply OEM spare parts for APV and WCB equipment, ensuring optimal performance and reliability. All parts are engineered for compatibility and extended service life.

We also offer expert onsite replacement, inspection, and commissioning to maintain uptime and product quality.

Choose SPX FLOW parts for lasting performance.

Contact us for technical support and service coordination.

-

Read More

APV UHT Sterilization System

APV UHT Sterilization SystemAPV UHT Sterilization System

APV UHT (Ultra High Temperature) Sterilization System

Delivers rapid and uniform sterilization for milk and liquid foods (135–150 °C), preserving flavor. Available in tubular, plate, or scraped-surface designs to match product needs.

Further information is available on the official SPX FLOW website:UHT system

Features:

Rapid heating/cooling minimizes thermal impact.

Fully automated CIP/SIP; HACCP and 3-A compliant.

Supports DSI or indirect (PHE/SSHE) heat modules.

Modular setup integrates with aseptic filling. -

Read More

APV Double Tube Sheet Cleanable Heat Exchanger

APV Double Tube Sheet Cleanable Heat ExchangerAPV Double Tube Sheet Cleanable Heat Exchanger

SPX FLOW APV ParaTube®

For ultra-hygienic applications in food, biotech, and pharma. DTS design ensures full separation of product and utility fluids, with independent leak detection.

Further information is available on the official SPX FLOW website:APV ParaTube®

Key Features:

DTS separation; 3-A, EHEDG, ASME BPE, FDA compliant.

Tube options: 316L, duplex, titanium.

Zero dead zones; CIP/SIP ready.

Configurations: multi/single/U/bent tubes.

Ideal for WFI, amino acids, fermentation, vaccines, injectables. -

Read More

Scraped Surface Heat Exchanger

Scraped Surface Heat ExchangerScraped Surface Heat Exchanger

APV Scraped Surface Heat Exchanger

Designed for high-viscosity and particulate-laden products, the APV scraped surface heat exchanger is ideal for food and pharmaceutical applications. Integrated scraper blades prevent fouling, improve heat transfer, and ensure consistent product quality.

Further information is available on the official SPX FLOW website:VT / HT Origin Series、VT+/HT+ Series

Key Features:

Versatile Application: Suitable for a broad viscosity range, with or without particulates.

Hygienic Design: Complies with CIP/SIP and aseptic standards.

Serviceability: Modular design enables quick access and fast scraper/seal replacement.

Robust Construction: 316L or duplex stainless steel, built for high pressure and temperature.

WCB Votator® II Horizontal Scraped Surface Heat Exchanger

Provides continuous, uniform thermal processing for viscous products. Offers high efficiency, hygienic operation, and straightforward maintenance.

Further information is available on the official SPX FLOW website:Votator® II Horizontal

Key Features:

High Pressure Rated: Standard up to 600 psi (42 bar), UStamp up to 800 psi (56 bar) at 204 °C.

Optimized Scraping: Continuous blade action minimizes fouling; PEEK™ options available.

Sanitary Construction: Meets 3-A, ASME, PED, FDA, CE; available in 316L, hard chrome, nickel, or duplex.

Direct-Drive Motor: Nord gear motor (5.5–22 kW), no belts or couplings.

Quick Service: VLock head, spline shaft, and removable heat tubes.

XHD Version: Handles viscosities up to 1,000,000 cP with enhanced torque and durability.

Applications: For fluids with particulates, crystallization tendency, or thermal sensitivity—such as sauces, pastes, and chocolate. Also suitable for cooling, sterilization, mixing, and crystallization processes. Widely used in industries such as food and dairy, edible oils and sauces, chemicals, pharmaceuticals, personal care, sugar, and meat processing.

-

Read More

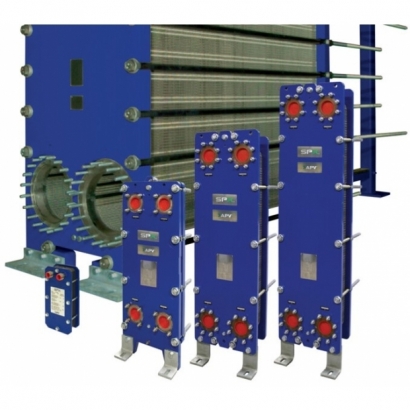

APV Plate Heat Exchanger

APV Plate Heat ExchangerAPV Plate Heat Exchanger

SPX offers advanced APV heat exchange solutions for fluid cooling, heating, condensing, and evaporation processes. Since the invention of the plate heat exchanger by APV in 1923, it has been a pioneer in applications such as stamping, forming, welding, sealing, and testing of plate materials.

In addition to providing industrial-grade plate heat exchangers with ASME U-Stamp certification, we also offer food hygiene grade plate heat exchangers certified by 3-A, FDA, and EHEDG.

• Various plate material options: SS304, SS316, SS317, 254SMO, 654SMO, 904L, C22, C276, C2000, Nickel Alloy 200/201, Ti Gr.1, Ti Gr.11/Gr.17.

• Maximum single plate area of 4.75m2 (approximately 4m high), maximum single interface diameter of φ500mm, maximum single processing flow rate of 4500 m3/hr.

• Laser-welded semi-welded plate heat exchangers are also available.

• With over 60 plate models, we can meet various heat exchange needs for liquid-liquid, evaporation, condensation, and gas-gas applications.

Advantages of APV plate heat exchanger technology:

1. Reliable plate interlocking structure and added suspension function.

2. Advanced Easyclip embedded gaskets require no glue for fixing, saving installation and cleaning time.

3. Efficient bypass zone design ensures uniform fluid distribution between channels, reducing resistance and improving heat transfer efficiency.

4. Double-layer leak prevention technology prevents fluid mixing at corner holes and makes it easier to identify leak positions.

5. Combination of soft and hard plate channel assembly allows for flexibility in design with different types of corrugated plates.

6. Various corrugated plate designs provide greater design flexibility.

Further information is available on the official SPX FLOW website:

Industrial Plate Heat Exchangers、Sanitary Plate Heat Exchangers -

Read More

APV Homogenizer

APV HomogenizerAPV Homogenizer

In the production process, the equipment used to achieve uniform emulsification or dispersion of products is called a homogenizer. Emulsification or dispersion refers to the phenomenon where solid-liquid or different phase liquids that cannot be mixed under normal conditions are subjected to fine mixing to achieve a uniform mixture. For example, the average particle size of fat globules in milk is typically 3μm to 22μm. After homogenization, it reduces to around 0.7μm to 1μm. Consequently, the buoyancy of fat globules disappears, and they can be fully mixed into the liquid (milk).

A homogenizer consists of a positive displacement pump and a homogenizing valve. The pump forces the product to pass through an adjustable gap and valve seat under high pressure, causing turbulence and intense mixing, thus breaking down molecular structures to achieve emulsification or dispersion.

Over 100 years of APV expertise in high-pressure homogenization:

Operating flow rate = 11~60000 L/hr

Operating pressure = 70~2000 Bar

Diverse modules, can provide special equipment according to customer requirements, including general industrial grade, explosion-proof grade, or food-grade models.

Homogenizing valve materials options: sanitary grade stainless steel, ceramic, tungsten carbide alloy, Stellite alloy steel.

Equipment equipped with lubrication and cooling systems for lubricating plungers and plunger seals.

The equipment can be cleaned online with cleaning solution or water using CIP.

Available in production units or laboratory units

Effects of high-pressure homogenization:

Reduce particle size

Improve product stability

Enhance viscosity and texture of products

Improve product hydration

Enhance product glossiness

Reduce the use of emulsifiers/stabilizers

Break down cells and extract intracellular substances

Increase chemical reactivity of substances

Enhance product absorption

Reduce molecular weight

Sample experiment services are provided, please contact the Taiwan Heat Transfer Business Department if needed.

Further information is available on the official SPX FLOW website:

Laboratory Homogenizers

Rannie 110T/125T - Gaulin 110T/125T Series

-

Read More

APV & WCB Food Grade Pump

APV & WCB Food Grade PumpAPV & WCB Food Grade Pump

APV Series

The W+ centrifugal pump series is built for hygienic processing in food, dairy, biotech, and pharma. Offers energy-efficient, low-shear performance. ATEX-certified models available.

Further information is available on the official SPX FLOW website:W+ Series (NEMA)、W+ Series (IEC)

Features:

Efficient hydraulics.

CIP/SIP ready design.

Balanced seals reduce wear.

Modular for ease of service.

Multiple impeller/material options.

WS+ Series

Upgraded for higher energy efficiency and reduced noise. Ideal for sound-sensitive, cost-conscious operations.

Further information is available on the official SPX FLOW website:WS+ Series (NEMA)、WS+ Series (IEC)

Features:

Redesigned impeller improves efficiency.

Low-noise structure.

Meets 3-A and EHEDG.

Flexible sealing options.

Compatible with W+ parts.

DW Series (Twin Screw Pump)

For shear-sensitive, high-viscosity applications. Enables gentle, precise fluid handling. Dry-run capable.

Further information is available on the official SPX FLOW website:Piston & Bi-Lobe Rotor Pumps

Features:

Stable flow across viscosity range.

Wear-resistant components.

Fully CIP/SIP compliant.

Designed for easy cleaning and quick disassembly.

WCB Series

WCB offers sanitary stainless steel pumps for hygienic applications.

Universal 2 Series

Further information is available on the official SPX FLOW website:Universal 2 Series Positive Displacement Pumps

Features:

Rotary positive displacement; up to 500 psi.

CIP-cleanable with bearing-free product zone, seal options.

Seal options; and stainless steel support frame

Universal 3 Series:

Further information is available on the official SPX FLOW website:Universal 3 Series Positive Displacement Pumps

Features:

Enhanced U2; front seals, thick shafts.

Improved vibration and pressure tolerance.

Aseptic, fully enclosed design. -

Read More

APV & WCB Food Grade Valves

APV & WCB Food Grade ValvesAPV & WCB Food Grade Valves

APV and WCB sanitary valves are trusted in hygienic processing across food, beverage, dairy, and pharma. Known for reliability, cleanability, and automation readiness.

APV Models:

DT4, D4/DA4: Mixproof valves.

SV/SVS: Butterfly valves.

BLV1: Ball valves for viscous fluids.

SW4: Single-seat control valves.

SD4: Double-seal CIP/divert valves.

RUF3: Check valves.

RG4: Control valves.

CPV, VRA/VRAH: Pressure/vacuum relief valves.

WCB Models:

W60 Series: Single-seat, CIP-ready.

W75CP, W75CP2 Series: Mixproof (W75CP, W75RS). -

Read More

APV Food Grade Production Line Equipment

APV Food Grade Production Line EquipmentAPV Food Grade Production Line Equipment

SPX Fluid can provide unit equipment and complete plant technology output for various beverages, alcoholic beverages, or dairy products.

The main unit equipment items are as follows:

• High-temperature sterilizer

• Online cleaning system (CIP)

• Falling film / rising film evaporator

• Distillation unit

• Flex-mix mixer

• Power-mixer high-shear emulsifier

Please contact the Taiwan Heat Transfer Sales Department for inquiries. -

Read More

Seital Centrifuge

Seital CentrifugeSeital Centrifuge

SPX FLOW's separators and clarifiers are based on advanced disk stack and highly efficient design. These equipments demonstrate particularly high performance in various processing applications, especially in the food and beverage industry.

Typical uses of centrifuges include:

• Clarification of liquids

• Separation of liquids

• Dehydration separation of suspensions and biomass

• Recovery of solid materials

• Extraction of valuable products

SPX FLOW's Seital centrifuges offer a variety of centrifuges for liquid-liquid, liquid-solid, or liquid-liquid-solid separation. Our centrifuges feature a self-cleaning design suitable for various high-demand processes, with processing capacities ranging from 500 l/h to 10,000 l/h (solids-retaining type) and 1,000 l/h to 70,000 l/h (self-cleaning type). All models are CIP capable. Utilize ultra-high centrifugal force to recover fine particles (0.5-500 mm) or separate clarified liquids.

Seven Advantages of SPX FLOW Seital Centrifuges:

• Short installation time - Modular equipment, no civil foundation, electrical or fluid testing required on-site.

• High performance - Innovative design developed using advanced software modeling tools, achieving precise mechanical and fluid analysis.

• High product quality - Use of mechanical seals to reduce oxidation risks, minimizing oxygen pick-up and CO2 loss.

• High uptime - Real-time operational diagnostics through remote monitoring, allowing for functional checks by technical personnel.

• Effective process control - Customized process adjustment settings.

• Lower maintenance requirements - Improved mechanical component reliability through high dynamic stability.

• Lower investment - Wide range of models and flexible accessory options.

Further information is available on the official SPX FLOW website:Seital Separation