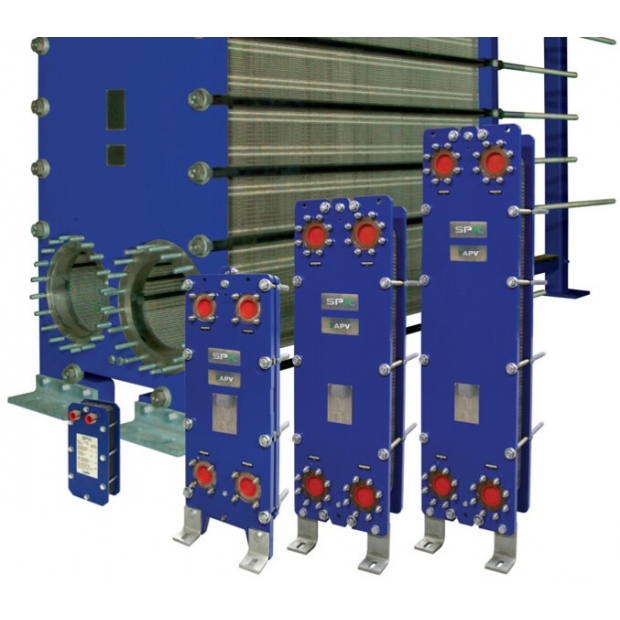

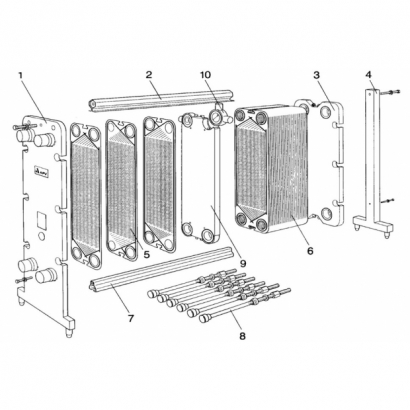

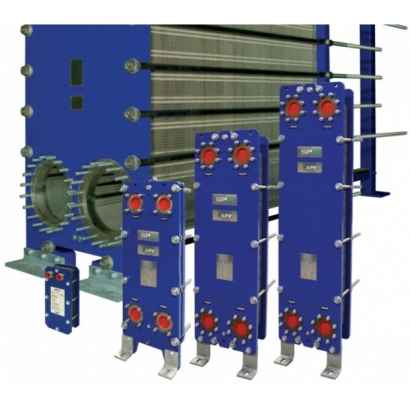

1. Variable Heat Transfer Area with Load: The number of heat transfer plates can be adjusted within the same frame according to the load.

2. Compact Size: The volume is approximately 1/4 to 1/5 of that of shell and tube heat exchangers for the same heat transfer capacity.

3. Lightweight: The weight is approximately half that of shell and tube heat exchangers for the same heat transfer capacity.

4. Cost-effective: Particularly advantageous for counter-current flow, especially in low temperature differential heat transfer scenarios.

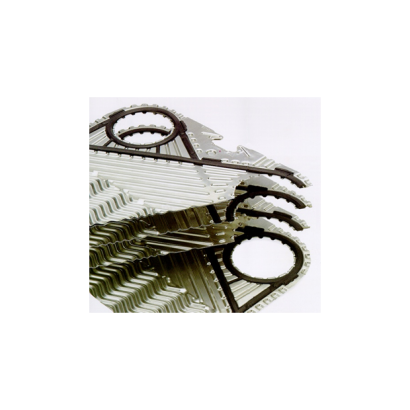

5. High Heat Transfer Efficiency: Internal flow fields are typically highly turbulent, resulting in a fouling resistance of only 10% to 25% compared to shell and tube heat exchangers.

Disadvantages of Plate Heat Exchangers (PHE):

Taiwan Heat Transfer can provide:1. Poor Pressure Resistance.

2. Risk of Gasket Leakage.

3. Narrow Passages Prone to Blockage.

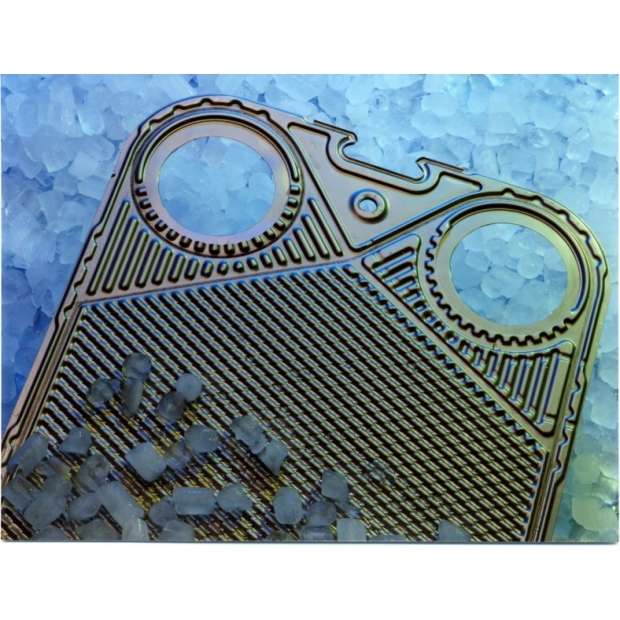

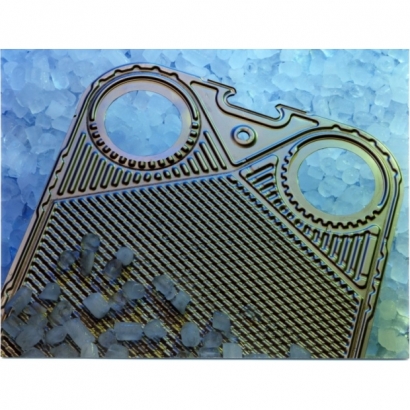

• Plate heat exchangers in various materials, including:

316 Stainless Steel, 317L Stainless Steel, 254SMO, AL6XN, Hastelloy, Incoloy, Titanium

• Plate heat exchangers with a variety of certifications, including:

ASME Pressure Vessel Certification, 3A/EHEDG Hygienic Certification for Food Applications,

AHRI Certification for HVAC and Refrigeration, FDA Compliance