Regardless of whether it's a nuclear power plant, thermal power plant, cogeneration plant, etc., as long as it utilizes a steam turbine for power generation, although the heat sources may vary, the principle of power generation remains the same. It involves utilizing a steam turbine for power generation, with the thermal cycle referred to as the steam power cycle or Rankine Cycle.

In the Rankine cycle of steam, feed water absorbs heat in the boiler (or steam generator) to produce steam, which is then sent through pipes to the turbine to expand and perform work, driving the generator for electricity generation. After performing work, the low-pressure exhausted steam is sent to the condenser for cooling, where it condenses into liquid form. It is then pumped back to the boiler through feed water pumps, passing through either high-pressure or low-pressure feed water heaters for reheating and through deaerators for thermal deaeration, thus forming a closed cycle.

Our Scope of Supply

Our company specializes in the design and manufacturing of a wide range of auxiliary heat exchange equipment used in power generation systems (excluding boilers), including:

- Surface Condensers

- Feedwater Heaters (Low-Pressure & High-Pressure)

- Deaerators

- Air Preheaters

- Gland Steam Condensers

- Air Ejectors

1. Release heat at the cold end and recover condensed exhausted steam to feed water.

2. Remove non-condensable gases and dissolved oxygen from water to prevent system corrosion.

3. Lower back pressure, maintain vacuum, increase turbine effective enthalpy drop, thereby enhancing cycle efficiency.

Condensers are classified into water-cooled (Surface Condenser) and air-cooled (Air Cooled Condenser), both of which our company can provide.

Vacuum level of the condenser is one of the main performance indicators. Our company can also provide vacuum equipment for the condenser, such as Air Ejectors and water ring vacuum pumps.

Feed Water Heater:

Feed Water Heater (FWH), its function is to heat feed water (boiler water) using extracted steam from the turbine, thus increasing the overall cycle efficiency, also known as regenerative heating. Feed water heaters include high-pressure heaters (HP) and low-pressure heaters (LP). Generally, the low-pressure heater (with lower tube-side pressure) is located between the condenser and deaerator, while the high-pressure heater (with higher tube-side pressure) is located after the feed water pump.

The advantages of using feed water heaters in power plants are as follows:

1. Improved thermal efficiency: Utilizing extracted steam for feed water heating reduces steam flow to the condenser, minimizing heat sink losses, thus enhancing cycle thermal efficiency.

2. For boilers, the increased feed water temperature reduces the boiler heat load, leading to a decrease in furnace heat exchange area, thereby saving energy and steel usage.

3. By having intermediate extraction steam, the steam flow to the last stages of the turbine is reduced, which in turn reduces the flow area of the last-stage turbine blades, addressing challenges in the design and manufacturing of turbine last-stage blades.

4. With reduced steam flow into the condenser, the heat load of the condenser decreases, reducing heat exchange area, thus saving investment costs and minimizing heat discharge to the environment.

Deaerator:

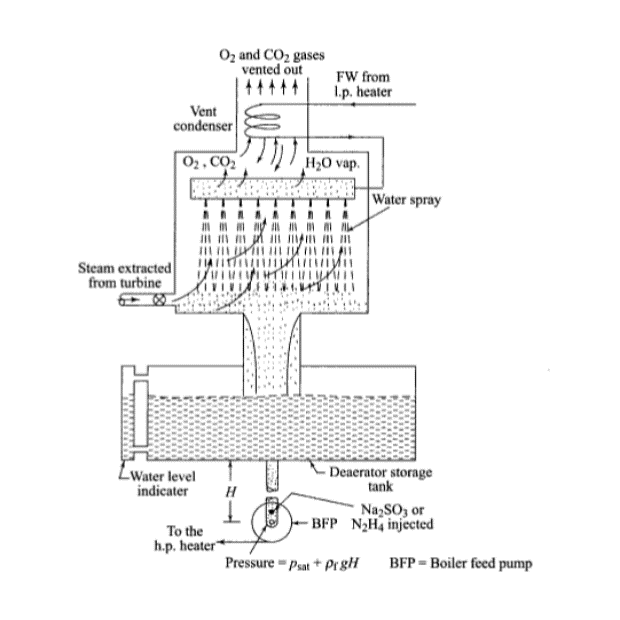

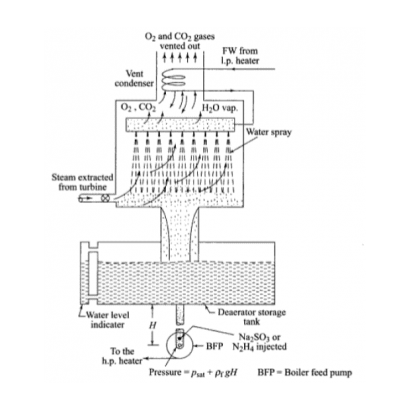

The deaerator is designed to remove dissolved oxygen from boiler feed water to protect the boiler from oxygen corrosion. Thermal deaeration is one of the primary methods for preventing corrosion in power plant boilers or industrial boilers.

In a deaerator, thermal deaeration is primarily used because the amount of gas dissolved in water is directly proportional to the partial pressure of the gas above the water surface (Henry's law). The principle is to use steam to heat feed water, increasing the water temperature and gradually increasing the partial pressure of steam above the water surface, while the partial pressure of dissolved gases gradually decreases.

As a result, gases dissolved in water continuously escape. When water is heated to the boiling temperature corresponding to the respective pressure, the water surface is entirely covered with water vapor, and the partial pressure of dissolved gases is zero. At this point, water no longer has the ability to dissolve gases, including oxygen. The effectiveness of deaeration depends on whether the feed water is heated to the boiling temperature corresponding to the respective pressure and the rate of gas removal, which is closely related to the contact surface area between water and steam.