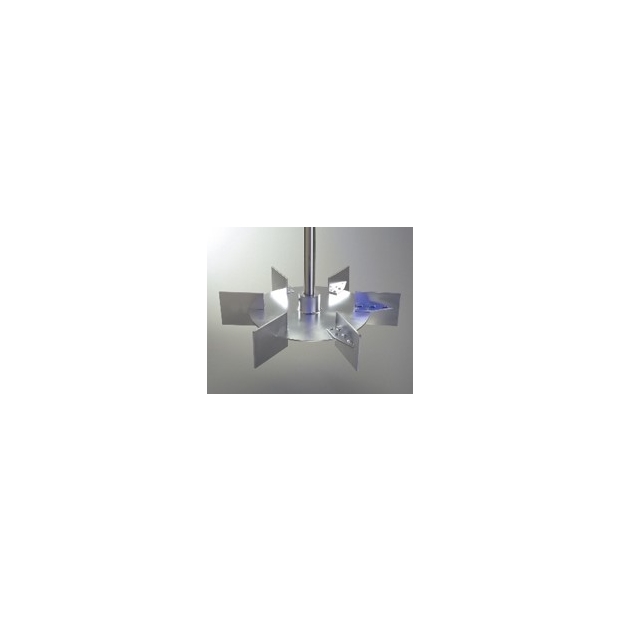

The three major elements in reactor design are process design, agitator, and vessel.

Taiwan Heat Transfer offers services including selection and design of reactors, testing of sample mixing effects, and Computational Fluid Dynamics (CFD) simulation of mixing effects, along with providing various types of mixing blades.

Taiwan Heat Transfer assists in various reaction process designs, such as:

1. Liquid-Solid: dissolution, suspension.

2. Liquid-Gas: absorption, dispersion.

3. Liquid-Liquid: extraction, emulsification.

4. Miscible Liquids: chemical reactions, physical mixing.

5. Fluid Movement: enhancing heat transfer, reducing precipitation.