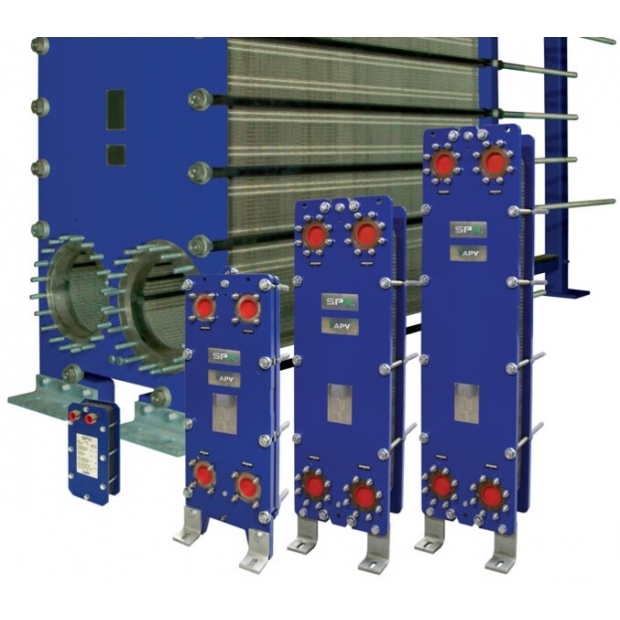

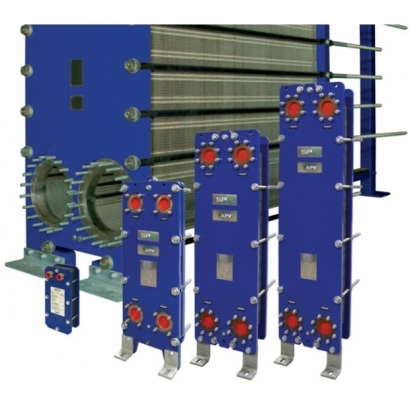

APV Plate Heat Exchanger

DETAIL

In addition to providing industrial-grade plate heat exchangers with ASME U-Stamp certification, we also offer food hygiene grade plate heat exchangers certified by 3-A, FDA, and EHEDG.

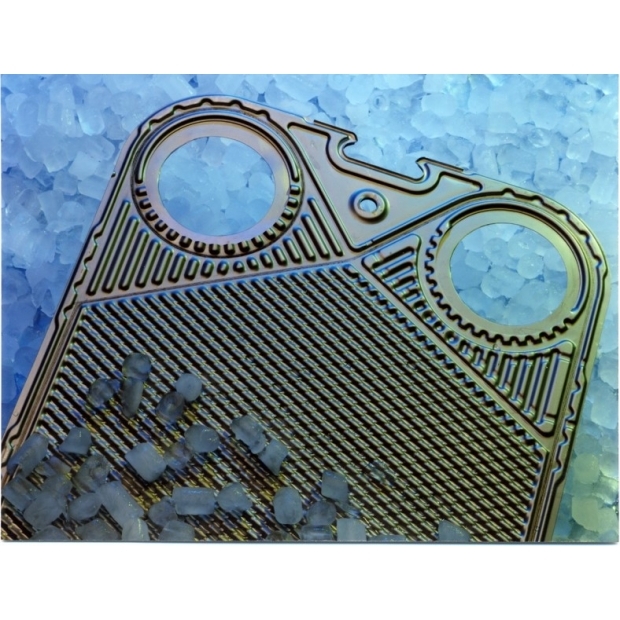

• Various plate material options: SS304, SS316, SS317, 254SMO, 654SMO, 904L, C22, C276, C2000, Nickel Alloy 200/201, Ti Gr.1, Ti Gr.11/Gr.17.

• Maximum single plate area of 4.75m2 (approximately 4m high), maximum single interface diameter of φ500mm, maximum single processing flow rate of 4500 m3/hr.

• Laser-welded semi-welded plate heat exchangers are also available.

• With over 60 plate models, we can meet various heat exchange needs for liquid-liquid, evaporation, condensation, and gas-gas applications.

Advantages of APV plate heat exchanger technology:

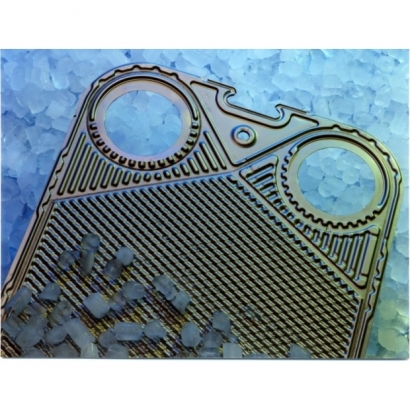

1. Reliable plate interlocking structure and added suspension function.

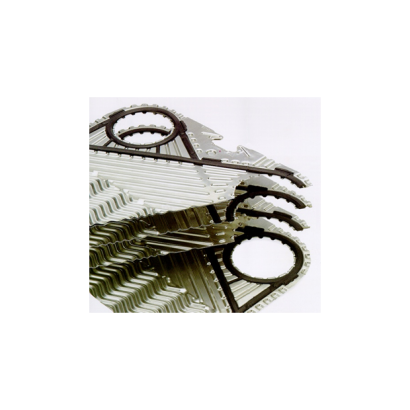

2. Advanced Easyclip embedded gaskets require no glue for fixing, saving installation and cleaning time.

3. Efficient bypass zone design ensures uniform fluid distribution between channels, reducing resistance and improving heat transfer efficiency.

4. Double-layer leak prevention technology prevents fluid mixing at corner holes and makes it easier to identify leak positions.

5. Combination of soft and hard plate channel assembly allows for flexibility in design with different types of corrugated plates.

6. Various corrugated plate designs provide greater design flexibility.

Further information is available on the official SPX FLOW website:

Industrial Plate Heat Exchangers、Sanitary Plate Heat Exchangers