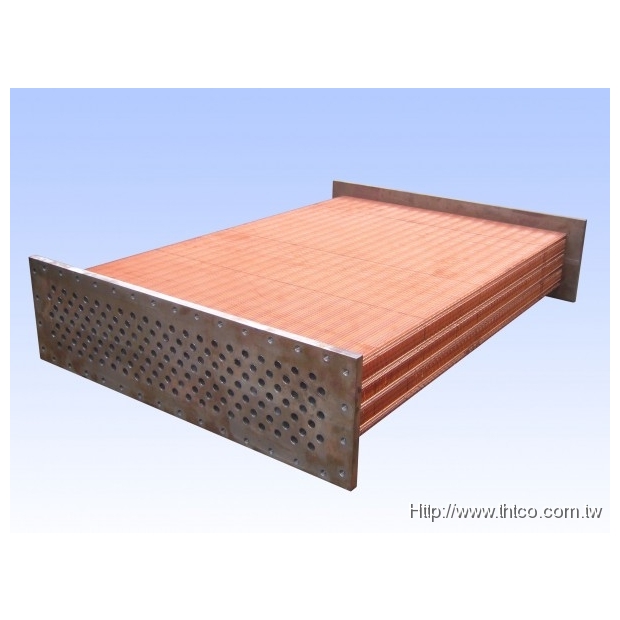

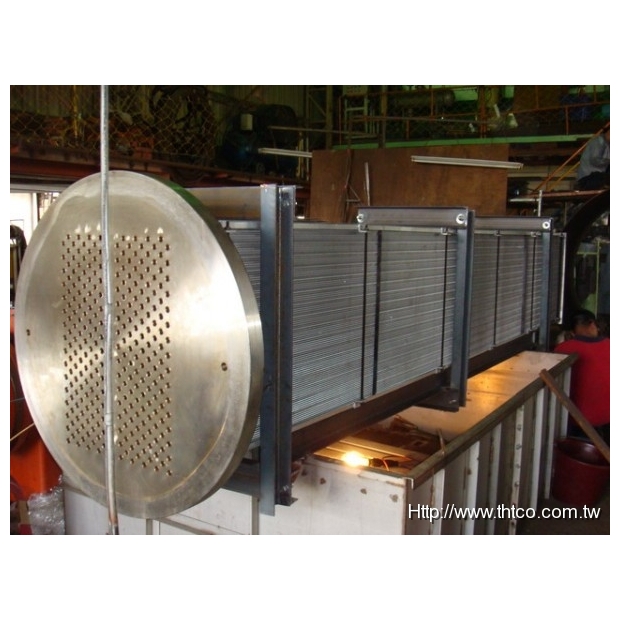

Finned tube heat exchangers have a structure similar to conventional shell-and-tube heat exchangers. However, instead of smooth tubes, finned tubes are used as the heat transfer surface. Due to enhanced heat transfer and compact structure, they are also known as compact heat exchangers. The primary purpose of adding fins is to increase the heat exchange surface area and promote heat exchange efficiency.

To increase the heating surface area, it can be achieved by increasing either the outer or inner surface. The additional area is referred to as the Secondary Area. Currently, there are various types of finned tubes used in the industry, with designs primarily focusing on external fins. External fins can be classified into several types: low finned tubes, high finned tubes, and continuous finned tubes. Selection of finned tubes depends on different operating conditions, and there are numerous options for the combination of fins and smooth tubes. Optimal selection can be made based on factors such as the type of fluid, operating temperature, and corrosiveness.

Taiwan Heat Transfer can provide various types of finned tube heat exchangers according to your specific requirements!

To increase the heating surface area, it can be achieved by increasing either the outer or inner surface. The additional area is referred to as the Secondary Area. Currently, there are various types of finned tubes used in the industry, with designs primarily focusing on external fins. External fins can be classified into several types: low finned tubes, high finned tubes, and continuous finned tubes. Selection of finned tubes depends on different operating conditions, and there are numerous options for the combination of fins and smooth tubes. Optimal selection can be made based on factors such as the type of fluid, operating temperature, and corrosiveness.

Taiwan Heat Transfer can provide various types of finned tube heat exchangers according to your specific requirements!