In the production process, the equipment used to achieve uniform emulsification or dispersion of products is called a homogenizer. Emulsification or dispersion refers to the phenomenon where solid-liquid or different phase liquids that cannot be mixed under normal conditions are subjected to fine mixing to achieve a uniform mixture. For example, the average particle size of fat globules in milk is typically 3μm to 22μm. After homogenization, it reduces to around 0.7μm to 1μm. Consequently, the buoyancy of fat globules disappears, and they can be fully mixed into the liquid (milk).

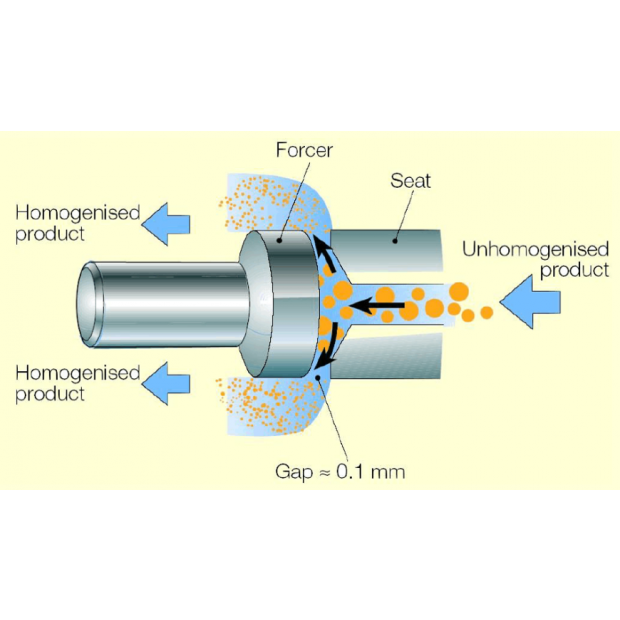

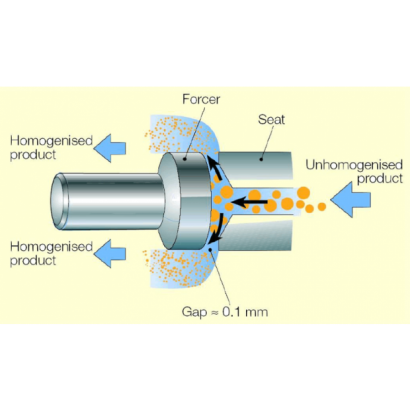

A homogenizer consists of a positive displacement pump and a homogenizing valve. The pump forces the product to pass through an adjustable gap and valve seat under high pressure, causing turbulence and intense mixing, thus breaking down molecular structures to achieve emulsification or dispersion.

Over 100 years of APV expertise in high-pressure homogenization:

- Operating flow rate = 11~60000 L/hr

- Operating pressure = 70~2000 Bar

Diverse modules, can provide special equipment according to customer requirements, including general industrial grade, explosion-proof grade, or food-grade models.

- Homogenizing valve materials options: sanitary grade stainless steel, ceramic, tungsten carbide alloy, Stellite alloy steel.

- Equipment equipped with lubrication and cooling systems for lubricating plungers and plunger seals.

- The equipment can be cleaned online with cleaning solution or water using CIP.

- Available in production units or laboratory units

Effects of high-pressure homogenization:

- Reduce particle size

- Improve product stability

- Enhance viscosity and texture of products

- Improve product hydration

- Enhance product glossiness

- Reduce the use of emulsifiers/stabilizers

- Break down cells and extract intracellular substances

- Increase chemical reactivity of substances

- Enhance product absorption

- Reduce molecular weight

.png)

Sample experiment services are provided, please contact the Taiwan Heat Transfer Business Department if needed.

Further information is available on the official SPX FLOW website:

Laboratory Homogenizers

Rannie 110T/125T - Gaulin 110T/125T Series