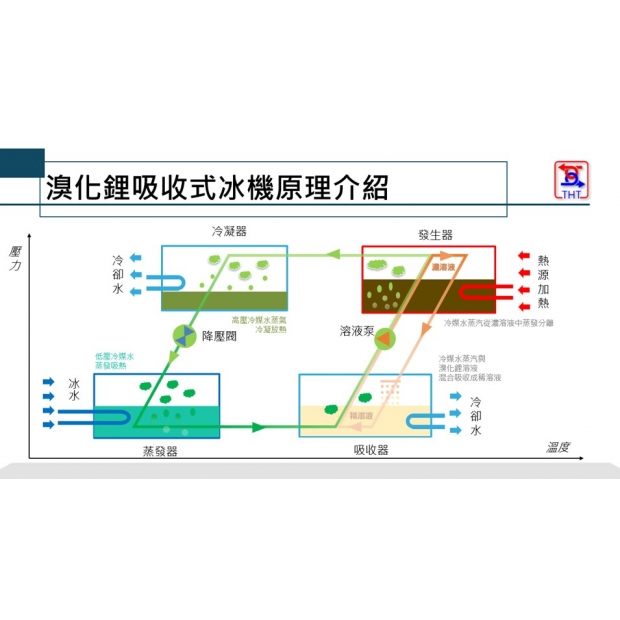

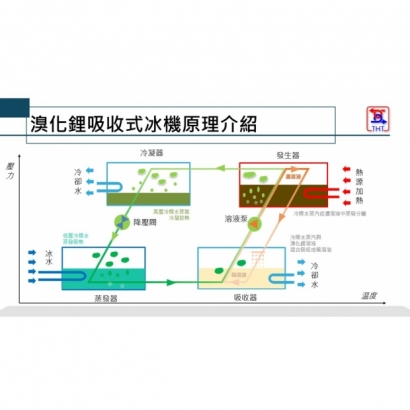

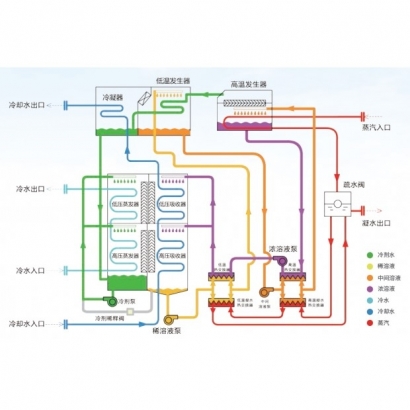

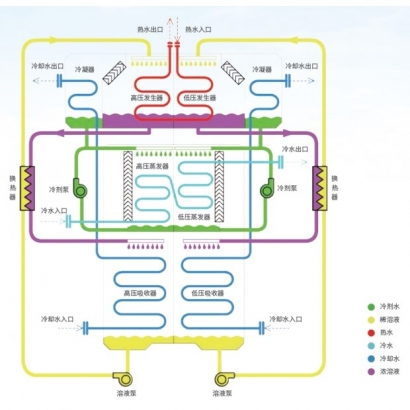

- Evaporator

- Condenser

- Generator

- Absorber

Water vapor and concentrated lithium bromide solution are separated in the generator → Vapor condenses into water in the condenser → Throttled to the evaporator for cooling → Absorbed by lithium bromide in the absorber to form a diluted solution → Returned to the generator.

Lithium Bromide Circulation (Replaces Compressor Function):

Concentrated solution from the generator → Pressure reduced via throttling → Absorbs water vapor in the absorber to form a diluted solution → Pumped back to the generator after pressurization.

Advantages:

- Simple structure with minimal mechanical components for stable, low-vibration operation.

- Easy operation with wide cooling capacity modulation from 10% to 100%.

- Compatible with low-grade heat sources such as waste heat, hot water, or steam.

- Driven by thermal energy; power consumption is only 5% of equivalent electric chillers.

- High cooling efficiency under stable heat supply and suitable for automation.

Limitations:

- Lithium bromide solution is corrosive to carbon steel; regular maintenance is required.

- Operates under vacuum; requires excellent sealing. Air leakage may lead to performance degradation.

- High cooling water demand.

- Single-effect hot water type: 30 RT to 3000 RT (also available in two-stage configuration)

- Single-effect / Double-effect steam type: 50 RT to 1500 RT

- Double-effect flue gas type: 100 RT to 1500 RT