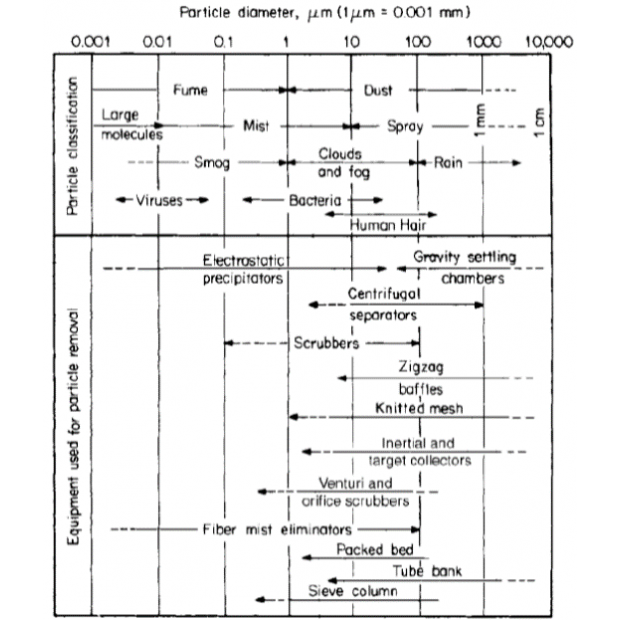

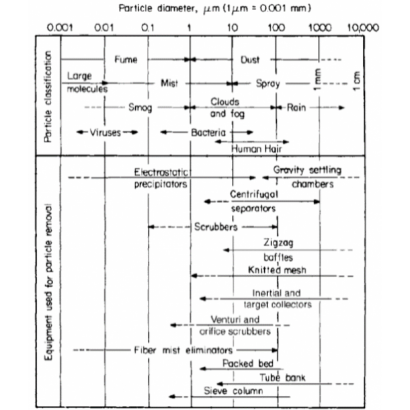

These methods can be used individually or in combination interchangeably. Their design features are as follows:1. Gravity separation.

2. Impingement force separation.

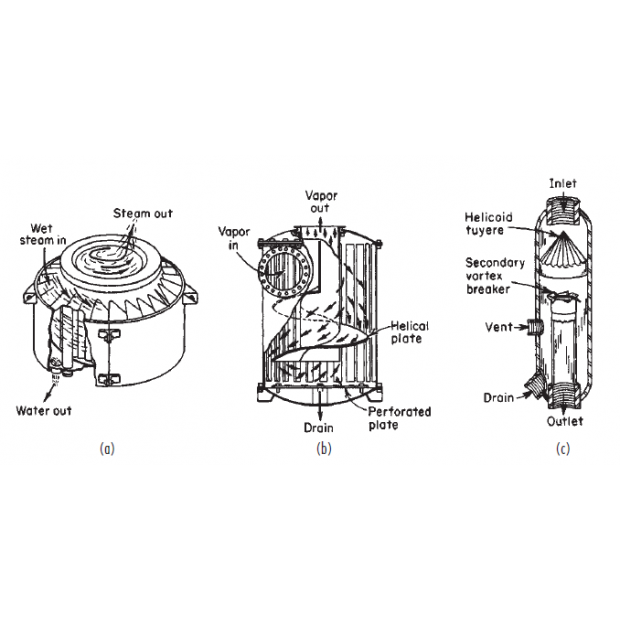

3. Centrifugal force separation.

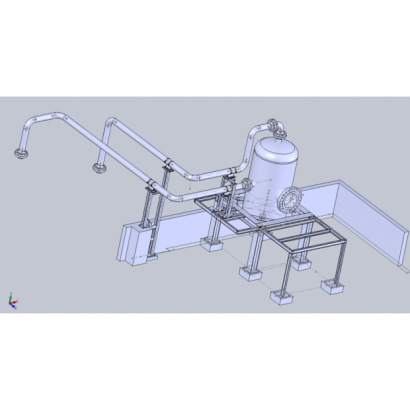

1. Gravity separation:

•Suitable for droplet sizes approximately > 100 μm.

• The principle of separation is that when the airflow flows upward in the container, droplets separate downward when their gravity exceeds the drag force of the airflow.

• To improve separation efficiency, it is advisable to avoid installing valves, feeding, or unnecessary redirection directly in front of the gravity separator.

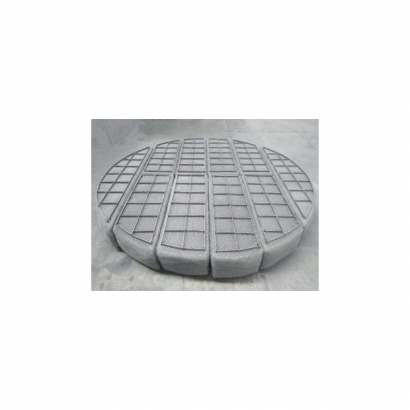

2. Impingement force separation:

• The working principle of this type of demister is to aggregate small liquid droplets by blocking wet steam.

• Types of designs include: 1. Wire-Mesh Type, 2. Chevron Type, 3. Fiber Bed. The material can be chosen based on the fluid type, and our developed pressure drop demisting efficiency calculation method can assist customers in dealing with unknown demisting efficiency designs.

Steam dryness measurement support is available upon request. Please contact Taiwan Heat Transfer's Sales Department for more details.3. Centrifugal force separation:

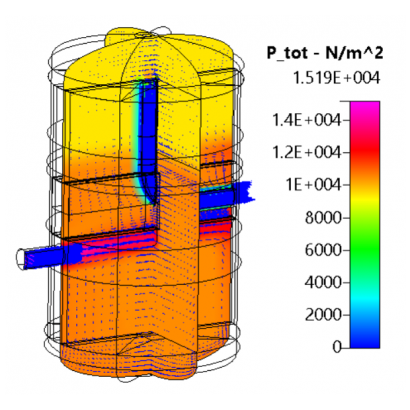

• Utilizes high-speed rotating airflow to subject liquid droplets (or particles) in the airflow to significant centrifugal force, thereby separating them.

• Centrifugal cyclone separators have a simple structure, low cost, and easy operation and maintenance. They can also be used in high-temperature and high-pressure environments. However, their drawback is the inability to separate droplets or particles with diameters that are too small.