All Project

-

Read More

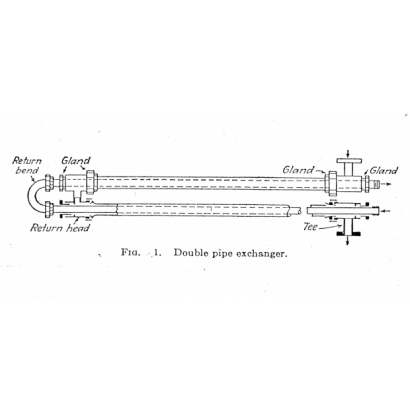

Double-Pipe Heat Exchanger

Double-Pipe Heat ExchangerDouble-Pipe Heat Exchanger

Double-Pipe Heat Exchangers are compact and simple heat transfer devices composed of two concentric tubes. They are known for their low cost, simple construction, and ease of maintenance. Each tube set has a limited heat transfer area, so multiple units must be arranged in series or parallel to meet higher capacity demands, which increases space usage and installation complexity.

These exchangers are typically used when the required heat transfer area is less than 20 m². While they are easy to clean and maintain, especially for fluids prone to scaling or crystallization, they are also prone to leakage due to thermal expansion when used in long configurations.

Key Features:

Simple structure: Easy to manufacture, install, and disassemble.

Modular flexibility: Multiple tube sets can be connected in series or parallel to expand capacity.

High durability: Suitable for high-pressure, high-temperature, or corrosive fluids.

Effective counterflow operation: High overall heat transfer efficiency, even under small temperature differences.

Excellent for viscous or fouling fluids: Ideal for syrups, brines, oils, resins, or fluids containing solids, thanks to their easy-clean design.

Double-pipe heat exchangers are commonly used in laboratories, food processing plants (especially for hygienic or high-viscosity applications), and industrial processes involving corrosive, high-pressure, or fouling-prone fluids.

In general, corrosive, high-temperature, or high-pressure fluids are routed through the inner tube. If both fluids are safe, the one with the higher flow rate typically flows through the larger flow area (outer tube), to optimize pressure drop and flow distribution.

-

Read More

Waste Heat Boiler

Waste Heat BoilerWaste Heat Boiler

Features

Waste heat boilers generate steam using flue gas or process gas. Unlike conventional heat exchangers, they have the following key characteristics:

Operate under high-pressure and high-temperature conditions.

Require control of outlet gas temperature and protection against dew point corrosion.

Structures and materials must withstand high temperature, high pressure, erosion, and corrosion.

Must account for scaling and blockage risks in the design process.

Pros and Cons

✔ Advantages

Energy-saving: Effectively recovers thermal energy from waste gas.

Compared to other heat recovery equipment, it offers high thermal conversion efficiency and rapid response.

✘ Limitation

3. Requires strict control of boiler water quality to prevent internal corrosion and scaling.

Design Features

Dry-out prevention is crucial, especially during startup or low-load conditions.

Higher evaporation pressure results in better heat transfer efficiency.

Inlet gas temperature should be close to the steam saturation temperature to minimize thermal stress.

Optimal design steam velocity:

– Recommended range: 10–20 m/s

– Excessive velocity may cause erosion and high pressure drop

– Low velocity may lead to unstable flow behavior

Hot point: Approximately 30°C above the steam saturation temperature.

Pinch Point: Typically 5–15°C

– A smaller temperature difference improves heat recovery but increases equipment cost

Approach Point: Typically 5–12°C

– The economizer outlet temperature should be slightly below the saturation temperature to avoid premature evaporation -

Read MoreElectric Heater

Electric Heater

We offer various custom-designed electric heater equipment, such as: electric tubular heaters, ceramic jacket heaters, and more.

Our designs can be systematized, incorporating various controls and protections.

✔ Electric heater materials are customizable according to requirements.

✔ We provide explosion-proof electric heaters.

✔ In addition, we offer infrared heaters. -

Read More

Pressure Vessel

Pressure VesselPressure Vessel

Taiwan Heat Transfer Company is a certified manufacturer of pressure vessels. We are qualified to produce Category I and Special High-Pressure (Category II) vessels in accordance with Taiwan’s pressure vessel regulations, as well as ASME U Stamp certified equipment.

We manufacture a wide range of pressure vessels, including towers, reactors, storage tanks, filters, and various types of heat exchangers. All equipment can be customized to meet specific process requirements.

Custom fabrication using various metal materials

Surface treatments such as polishing and corrosion resistance

Food-grade (aseptic) designs available upon request

Integration of coils, jackets, agitators, and process control features

Assistance with equipment certification, modification inspections, final inspections, and safety valve selection

If you are unsure whether your equipment qualifies as a pressure vessel, please refer to the "Pressure Vessel Determination Process" in the technical information section of our website, or contact our sales department for support.

-

Read More

Food Grade Equipment

Food Grade EquipmentFood Grade Equipment

SPX FLOW – Hygienic Processing Equipment

As an authorized distributor of SPX FLOW, we bring over 60 years of experience in food-grade hygienic equipment. SPX FLOW works closely with customers throughout the equipment lifecycle, providing expert support to help optimize product quality, yield, and food safety—while reducing raw material waste, energy use, and overall costs.

Our hygienic-grade equipment includes:

Pumps (centrifugal, screw, lobe, gear)

Valves

Heat exchangers (plate, shell-and-tube, double-tube-sheet, tubular, scraped surface)

Sterilization systems

Homogenizers

Centrifuges

Storage vessels (pressure vessels, reactors, tanks)

Hygienic design standards:

Surface finishes: electropolishing, mechanical polishing

International certifications: FDA, EHEDG, 3-A

Cleaning compatibility: CIP, SIP

Applications:

Food & beverage

Dairy and soy products

Pharmaceuticals and nutraceuticals

Sauces and condiments

Brewing and alcoholic beverages

-

Read More

Reactors and Agitators

Reactors and AgitatorsReactors and Agitators

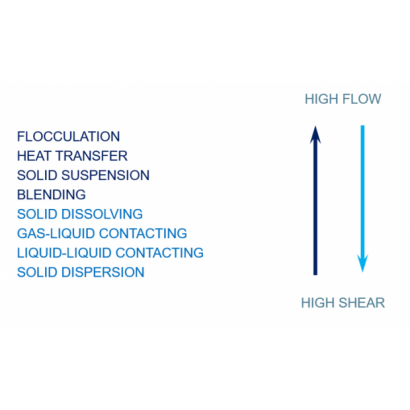

In manufacturing processes, equipment is employed to provide reaction space and conditions for chemical reactions or physical transformations, which can be either batch or continuous. Thorough mixing of the participating reaction media facilitates material blending, while the reaction process can be heated or cooled using jacketing or coil systems. This equipment can enhance heat transfer efficiency or interphase mass transfer.

The three major elements in reactor design are process design, agitator, and vessel.

Taiwan Heat Transfer offers services including selection and design of reactors, testing of sample mixing effects, and Computational Fluid Dynamics (CFD) simulation of mixing effects, along with providing various types of mixing blades.

Taiwan Heat Transfer assists in various reaction process designs, such as:

1. Liquid-Solid: dissolution, suspension.

2. Liquid-Gas: absorption, dispersion.

3. Liquid-Liquid: extraction, emulsification.

4. Miscible Liquids: chemical reactions, physical mixing.

5. Fluid Movement: enhancing heat transfer, reducing precipitation. -

Read More

Dryer

DryerDryer

Taiwan Heat Transfer specializes in custom designing various types of drying equipment, including hot air dryers, vacuum dryers, freeze dryers, and sludge dryers.

Drying methods include hot air drying, drum drying, agitated drying, and cyclone separation.

Our designs can be systematized, incorporating control systems, heat recovery systems, and other features. -

Read More

Demister / Gas-Liquid Separator

Demister / Gas-Liquid SeparatorDemister / Gas-Liquid Separator

Taiwan Heat Transfer specializes in designing various demisters/liquid-gas separators, which are primarily designed using the following three methods:

1. Gravity separation.

2. Impingement force separation.

3. Centrifugal force separation.

These methods can be used individually or in combination interchangeably. Their design features are as follows:

1. Gravity separation:

•Suitable for droplet sizes approximately > 100 μm.

• The principle of separation is that when the airflow flows upward in the container, droplets separate downward when their gravity exceeds the drag force of the airflow.

• To improve separation efficiency, it is advisable to avoid installing valves, feeding, or unnecessary redirection directly in front of the gravity separator.

2. Impingement force separation:

• The working principle of this type of demister is to aggregate small liquid droplets by blocking wet steam.

• Types of designs include: 1. Wire-Mesh Type, 2. Chevron Type, 3. Fiber Bed. The material can be chosen based on the fluid type, and our developed pressure drop demisting efficiency calculation method can assist customers in dealing with unknown demisting efficiency designs.

3. Centrifugal force separation:

• Utilizes high-speed rotating airflow to subject liquid droplets (or particles) in the airflow to significant centrifugal force, thereby separating them.

• Centrifugal cyclone separators have a simple structure, low cost, and easy operation and maintenance. They can also be used in high-temperature and high-pressure environments. However, their drawback is the inability to separate droplets or particles with diameters that are too small.

Steam dryness measurement support is available upon request. Please contact Taiwan Heat Transfer's Sales Department for more details. -

Read More

Special Metal Welding

Special Metal WeldingSpecial Metal Welding

The P-Number system is established by ASME to classify materials based on their weldability. It is primarily used for WPS/PQR documentation and material compatibility analysis.

Our welding capabilities cover the material groups listed in the table below:

Material Type

ASME P-Group

Representative Materials & Standards

Common Applications & Characteristics

Carbon Steel

P-1

SA-516 Gr.70, SA-106 Gr.B, SA-36, SA-105

Commonly used in pressure vessels and piping; cost-effective and easy to fabricate

Low Alloy Steel

P-2, P-5, P-10, P-11

SA-182 F5/F9, SA-213 T22, SA-335 P11/P22, SA-517

Suitable for high-temperature and high-pressure systems, such as boilers and thermal oil systems

Austenitic Stainless Steel

P-8

304 / 316 / 321 / 347 / 309 / 310 (SA-240, SA-182)

Excellent corrosion resistance; widely used for general industrial applications

Duplex Stainless Steel

P-10h

S31803 / S32205 / S32750 (SA-240, SA-789)

High strength and excellent corrosion resistance; commonly used in seawater and chloride environments

Pure Nickel

P-10i

Nickel 200 / 201 (SB-162)

Excellent resistance to acids and alkalis; ideal for highly corrosive environments (also known as Monel®)

Nickel Alloys: Ni-Cu

P-10j

Alloy 400 (SB-127, SB-564)

Resistant to chloride stress corrosion cracking; suitable for marine environments (also known as Monel®)

Nickel Alloys: Ni-Cr

P-10j

Alloy 600 / 601 (SB-168)

Excellent oxidation resistance at high temperatures; often used in furnaces and high-temp tubing (Inconel®)

Nickel Alloys: Ni-Mo

P-10k

Alloy B / B-2 (SB-333, SB-335)

Exceptional resistance to hydrochloric acid and other aggressive media (e.g., Hastelloy® B series)

Nickel Alloys: Ni-Cr-Mo

P-10k

Alloy C-276 / C-2000 (SB-575)

Superior resistance to a wide range of corrosive chemicals; ideal for chemical and pharmaceutical systems (Hastelloy® C series)

Nickel Alloys: Fe-Ni-Cr

P-10j

Alloy 800 / 825 (SB-407)

High resistance to heat and corrosion; excellent thermal stability (Incoloy® series)

Copper & Copper Alloys

P-31

C12200 (red copper), C70600 (Cu-Ni), C44300 (naval brass, Cu-Zn 70/30), C71500 (Cu-Ni 70/30), C68700 (aluminum brass)

Commonly used in general-purpose heat exchangers

Titanium

No defined P-Group

Grade 1–2 (SB-265, SB-338, SB-348)

Excellent resistance to seawater and salt environments; high corrosion resistance but limited heat resistance