All Agent

-

Read More

APV Homogenizer

APV HomogenizerAPV Homogenizer

In the production process, the equipment used to achieve uniform emulsification or dispersion of products is called a homogenizer. Emulsification or dispersion refers to the phenomenon where solid-liquid or different phase liquids that cannot be mixed under normal conditions are subjected to fine mixing to achieve a uniform mixture. For example, the average particle size of fat globules in milk is typically 3μm to 22μm. After homogenization, it reduces to around 0.7μm to 1μm. Consequently, the buoyancy of fat globules disappears, and they can be fully mixed into the liquid (milk).

A homogenizer consists of a positive displacement pump and a homogenizing valve. The pump forces the product to pass through an adjustable gap and valve seat under high pressure, causing turbulence and intense mixing, thus breaking down molecular structures to achieve emulsification or dispersion.

Over 100 years of APV expertise in high-pressure homogenization:

Operating flow rate = 11~60000 L/hr

Operating pressure = 70~2000 Bar

Diverse modules, can provide special equipment according to customer requirements, including general industrial grade, explosion-proof grade, or food-grade models.

Homogenizing valve materials options: sanitary grade stainless steel, ceramic, tungsten carbide alloy, Stellite alloy steel.

Equipment equipped with lubrication and cooling systems for lubricating plungers and plunger seals.

The equipment can be cleaned online with cleaning solution or water using CIP.

Available in production units or laboratory units

Effects of high-pressure homogenization:

Reduce particle size

Improve product stability

Enhance viscosity and texture of products

Improve product hydration

Enhance product glossiness

Reduce the use of emulsifiers/stabilizers

Break down cells and extract intracellular substances

Increase chemical reactivity of substances

Enhance product absorption

Reduce molecular weight

Sample experiment services are provided, please contact the Taiwan Heat Transfer Business Department if needed.

Further information is available on the official SPX FLOW website:

Laboratory Homogenizers

Rannie 110T/125T - Gaulin 110T/125T Series

-

Read More

APV & WCB Food Grade Pump

APV & WCB Food Grade PumpAPV & WCB Food Grade Pump

APV Series

The W+ centrifugal pump series is built for hygienic processing in food, dairy, biotech, and pharma. Offers energy-efficient, low-shear performance. ATEX-certified models available.

Further information is available on the official SPX FLOW website:W+ Series (NEMA)、W+ Series (IEC)

Features:

Efficient hydraulics.

CIP/SIP ready design.

Balanced seals reduce wear.

Modular for ease of service.

Multiple impeller/material options.

WS+ Series

Upgraded for higher energy efficiency and reduced noise. Ideal for sound-sensitive, cost-conscious operations.

Further information is available on the official SPX FLOW website:WS+ Series (NEMA)、WS+ Series (IEC)

Features:

Redesigned impeller improves efficiency.

Low-noise structure.

Meets 3-A and EHEDG.

Flexible sealing options.

Compatible with W+ parts.

DW Series (Twin Screw Pump)

For shear-sensitive, high-viscosity applications. Enables gentle, precise fluid handling. Dry-run capable.

Further information is available on the official SPX FLOW website:Piston & Bi-Lobe Rotor Pumps

Features:

Stable flow across viscosity range.

Wear-resistant components.

Fully CIP/SIP compliant.

Designed for easy cleaning and quick disassembly.

WCB Series

WCB offers sanitary stainless steel pumps for hygienic applications.

Universal 2 Series

Further information is available on the official SPX FLOW website:Universal 2 Series Positive Displacement Pumps

Features:

Rotary positive displacement; up to 500 psi.

CIP-cleanable with bearing-free product zone, seal options.

Seal options; and stainless steel support frame

Universal 3 Series:

Further information is available on the official SPX FLOW website:Universal 3 Series Positive Displacement Pumps

Features:

Enhanced U2; front seals, thick shafts.

Improved vibration and pressure tolerance.

Aseptic, fully enclosed design. -

Read More

APV & WCB Food Grade Valves

APV & WCB Food Grade ValvesAPV & WCB Food Grade Valves

APV and WCB sanitary valves are trusted in hygienic processing across food, beverage, dairy, and pharma. Known for reliability, cleanability, and automation readiness.

APV Models:

DT4, D4/DA4: Mixproof valves.

SV/SVS: Butterfly valves.

BLV1: Ball valves for viscous fluids.

SW4: Single-seat control valves.

SD4: Double-seal CIP/divert valves.

RUF3: Check valves.

RG4: Control valves.

CPV, VRA/VRAH: Pressure/vacuum relief valves.

WCB Models:

W60 Series: Single-seat, CIP-ready.

W75CP, W75CP2 Series: Mixproof (W75CP, W75RS). -

Read More

APV Food Grade Production Line Equipment

APV Food Grade Production Line EquipmentAPV Food Grade Production Line Equipment

SPX Fluid can provide unit equipment and complete plant technology output for various beverages, alcoholic beverages, or dairy products.

The main unit equipment items are as follows:

• High-temperature sterilizer

• Online cleaning system (CIP)

• Falling film / rising film evaporator

• Distillation unit

• Flex-mix mixer

• Power-mixer high-shear emulsifier

Please contact the Taiwan Heat Transfer Sales Department for inquiries. -

Read More

Seital Centrifuge

Seital CentrifugeSeital Centrifuge

SPX FLOW's separators and clarifiers are based on advanced disk stack and highly efficient design. These equipments demonstrate particularly high performance in various processing applications, especially in the food and beverage industry.

Typical uses of centrifuges include:

• Clarification of liquids

• Separation of liquids

• Dehydration separation of suspensions and biomass

• Recovery of solid materials

• Extraction of valuable products

SPX FLOW's Seital centrifuges offer a variety of centrifuges for liquid-liquid, liquid-solid, or liquid-liquid-solid separation. Our centrifuges feature a self-cleaning design suitable for various high-demand processes, with processing capacities ranging from 500 l/h to 10,000 l/h (solids-retaining type) and 1,000 l/h to 70,000 l/h (self-cleaning type). All models are CIP capable. Utilize ultra-high centrifugal force to recover fine particles (0.5-500 mm) or separate clarified liquids.

Seven Advantages of SPX FLOW Seital Centrifuges:

• Short installation time - Modular equipment, no civil foundation, electrical or fluid testing required on-site.

• High performance - Innovative design developed using advanced software modeling tools, achieving precise mechanical and fluid analysis.

• High product quality - Use of mechanical seals to reduce oxidation risks, minimizing oxygen pick-up and CO2 loss.

• High uptime - Real-time operational diagnostics through remote monitoring, allowing for functional checks by technical personnel.

• Effective process control - Customized process adjustment settings.

• Lower maintenance requirements - Improved mechanical component reliability through high dynamic stability.

• Lower investment - Wide range of models and flexible accessory options.

Further information is available on the official SPX FLOW website:Seital Separation -

Read More

Shuangliang Air Cooling

Shuangliang Air CoolingShuangliang Air Cooling

Our company, in collaboration with Shuangliang, pioneered the promotion of Flat Tube ACC (Air Cooled Condenser) in Taiwan. Clyde Bergemann, established in 2014 in cooperation with Shuangliang, focuses on the development of air-cooling technology.

Shuangliang's air cooling technology boasts complete independent intellectual property rights, replacing traditional water cooling with air cooling, applicable in power generation units and process cooling, with a water saving rate of over 85%. (For example, in a 1 million kilowatt thermal power plant, it can save at least 100 million tons of water per year, equivalent to the annual water consumption of 500,000 urban residents.)

Research and development achievements include air-cooled anti-freezing test research, million-unit seismic test research, and wind engineering research on intercooler towers, leading the industry's technological advancement.

Our company provides industry-leading Flat Tube ACC products, based on robust research and manufacturing capabilities.

Three major testing facilities ensure overall product performance:

Bundle performance test device, used to obtain optimized flat tube designs and more accurate heat transfer data.

Shuangliang has set up a 1:1 1000MW level ACC prototype in the park, which is the industry's only large-scale hot-state air cooling test system.

The industry's unique air-cooling test laboratory (-25 ℃ to 40 ℃) and environmental test facility.

Nine test researches thoroughly analyze the performance of heat exchange components:

Test research on heat exchange performance of heat exchange components.

Test research on air-side resistance characteristics of heat exchange components.

Test research on steam-side resistance characteristics of heat exchange component tubes.

Aluminum fin atmospheric corrosion performance test research.

Weld seam and corrosion resistance test of base tube.

Bundle fouling performance test.

Bundle flushing test.

Anti-freezing test research of bundle.

Air-cooled bundle fatigue test. -

Read More

Heat Exchange Equipment for Power Plants

Heat Exchange Equipment for Power PlantsHeat Exchange Equipment for Power Plants

During the power generation process in power plants, steam power cycles (Rankine cycles) are utilized, which include processes such as constant pressure heat absorption, isentropic expansion, constant pressure heat rejection, and isentropic compression. Additionally, reheating cycles and regenerative cycles are often incorporated.

In the power generation cycle, our company collaborates with Shuangliang Group to provide customers with all auxiliary equipment for power plants besides turbines and boilers. These include:

Surface Condenser

Air Cooled Condenser

LP Feed Water Heater

HP Feed Water Heater

Deaerator

Air Ejector

Water Ring Vacuum Pump

Gland Steam Condenser -

Read More

Shuangliang High Efficiency Heat Exchanger

Shuangliang High Efficiency Heat ExchangerShuangliang High Efficiency Heat Exchanger

Shuangliang is capable of designing and providing various advanced and efficient heat exchanger products, and is the only equipment manufacturer in the industry that provides fluid analysis and structural optimization analysis, capable of providing customers with front-end process design and structural simulation analysis.

Our technical capabilities include:

G-type finned tube: Reasonable tube arrangement, low shell-side pressure drop, saving energy by 20%. Withstands high temperatures up to 400℃.

Double pipe plate structure: The double pipe plate structure effectively prevents contact between tube-side steam and shell-side nitrogen.

Single pipe plate deep hole structure: Single plate + deep hole safety ring plate structure.

Stress analysis: Overall structural stress analysis, higher design reliability.

Deep hole welding: Fatigue resistance, best sealing butt welding method, using imported French Polysoude welding machine with "steady flow circuit power supply, walking accuracy compensation" for one-time welding.

Large bundle assembly: Small diameter, thin wall, super long (27 meters long heat exchange tube) heat exchange tube surface protection assembly, non-traditional center positioning butt welding for tube holes and heat exchange tubes.

Comprehensive helium leak detection: Improved helium leak detection fixtures, helium leak detection using suction gun method, meeting European and Japanese standards requirements. -

Read More

Shuangliang Seawater Desalination

Shuangliang Seawater DesalinationShuangliang Seawater Desalination

Low Temperature-Multi Effect Distillation (MED) for seawater desalination refers to a desalination technology where the highest brine temperature (TBT) does not exceed 70°C, characterized by a series of horizontal (or vertical) tube falling film evaporators connected in series and divided into several effect groups. A certain amount of steam is inputted through multiple evaporation and condensation cycles, resulting in distilled water multiple times the amount of heating steam.

Technical Features:

Adaptability to different high and low-grade waste heat situations, improving overall efficiency.

Low operating temperature to avoid or reduce equipment corrosion and scaling.

No need for complex pretreatment of seawater, suitable for various changes in seawater conditions.

Stable and reliable device operation, with low maintenance and repair requirements, and low cost.

Strong load adaptability, with an adjustment range of 40% to 110%.

High product water quality with a salt content lower than 5mg/L.

Application Scenarios:

Suitable for large and medium-sized seawater desalination plants utilizing high and low-grade steam provided by power plants and chemical plants, especially suitable for utilizing low-grade waste heat.

The product water has extremely high purity and can be used as boiler makeup water, process water in production processes, or for large-scale municipal drinking water supply. -

Read More

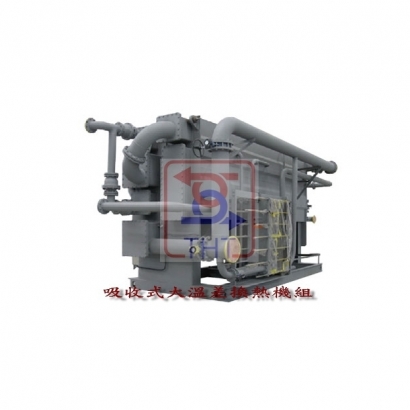

Lithium Bromide Absorption Chiller

Lithium Bromide Absorption ChillerLithium Bromide Absorption Chiller

Main Heat Exchange Components of a Lithium Bromide Absorption Chiller:

Evaporator

Condenser

Generator

Absorber

Refrigerant Water Cycle:

Water vapor and concentrated lithium bromide solution are separated in the generator → The vapor condenses into water in the condenser → Passes through a throttle valve →

Evaporates and absorbs heat in the evaporator → Mixes with lithium bromide in the absorber to form a dilute solution → Returned to the generator.

Lithium Bromide Cycle (Performs the function of a compressor):

Water vapor is separated in the generator, forming a concentrated solution → Pressure is reduced through throttling → In the absorber, the solution absorbs water vapor and becomes a dilute solution → The dilute solution is pumped to increase pressure → Returned to the generator.

Advantages

Simple structure with few mechanical moving parts; smooth operation and low vibration.

Easy to operate, with a wide range of cooling capacity adjustment (stepless control from 10% to 100%).

Low energy quality requirements: steam or hot water-driven units can utilize waste heat, residual heat, or other low-grade heat sources.

Thermal energy-driven: power consumption is only 5% of that of a mechanical compression chiller with the same cooling capacity.

Stable cooling efficiency when the heat source is stable, and capable of fully automated control.

Disadvantages

Lithium bromide solution is corrosive to carbon steel, requiring regular maintenance and protection.

The unit operates under vacuum conditions, requiring high airtightness; air ingress will cause performance degradation.

Still requires cooling water for operation.

Conditions for Using Lithium Bromide Absorption Chillers:

Ø Energy-saving!!! No compressor required!!!

Ø Available waste steam pressure ≥ 30 kPa, or waste hot water temperature ≥ 80°C

Ø Waste heat source capacity > 500,000 kcal/hr (approx. 581 kW)

Ø Or equivalent fluid conditions such as waste gas, exhaust air, or wastewater with the above heat parameters

Ø Cooling capacity demand > 100 RT (≈ 350 kW)

Ø Required chilled water temperature ≥ 5°C

Ø Initial investment is approximately twice that of a conventional mechanical chiller

Official Website

Hua Yuan Tai Meng (a subsidiary of MOON-TECH Group)

http://http://www.powerbeijinghytm.com/ -

Read More

Industrial Low-Temperature Refrigeration System

Industrial Low-Temperature Refrigeration SystemIndustrial Low-Temperature Refrigeration System

MOON-TECH Low-Temperature Refrigeration (Brine) Systems

MOON-TECH provides refrigeration technology covering a temperature range from 0°C to -160°C, ideal for industrial low-temperature applications.

Core Technology

MOON-TECH’s brine refrigeration systems are built around self-developed screw compressors, paired with a variety of evaporators, condensers, and oil circulation systems.

✔ Simple operation

✔ Stable outlet temperature

✔ Optional ASME certification

✔ Optional explosion-proof configuration

Supported Refrigerants

R134a, R507, R410, R404, R23

Ethylene (E1150), Propylene (E1270), Ethane (R170), Propane (R290)

NH₃ (Ammonia, R717), CO₂ (Carbon dioxide, R744)

System Types by Temperature Range

Temperature Range

System Configuration

0°C to -25°C

: Single-stage screw compressor units

-25°C to -50°C

: Two-stage twin screw compressor units or NH₃/CO₂ cascade systems

-50°C to -100°C

: R23 / E1150 (Ethylene) two-stage cascade systems

Available Options

MOON-TECH also offers brine systems using conventional HFC refrigerants or ammonia (NH₃) based on project-specific needs.

-

Read More

Process Compressor / Booster

Process Compressor / BoosterProcess Compressor / Booster

MOON-TECH’s process gas compressors adopt screw-type technology, available in both oil-injected and oil-free configurations.

Pressure range: from micro pressure up to 6.4 MPa

Certifications available: API 619, CE, and Explosion-proof certification

Industrial process gas compressors or boosters play an essential role in the energy and chemical industries. MOON-TECH offers high-performance compressors suitable for handling a variety of gases such as:

Steam, biogas, refrigerants, analytical gases, flash steam, methane, ethylene, propane, propylene, pentafluoropropane, water gas, ammonia, acetylene, chloromethane, carbon dioxide, vinyl chloride, sulfur dioxide, nitrogen, hydrogen, helium, and other industrial gases for compression and even liquefaction.

These units meet the boosting demands of multiple processes such as light hydrocarbon recovery, gas gathering, LNG liquefaction, and carbon capture across sectors like petroleum and natural gas.

Single Unit Compressor Capacity:

Inlet flow rate: 100–15,000 m³/h

Suction pressure: -0.05–2.0 MPaG

Discharge pressure: 0.1–5.0 MPaG

Motor power: 22–3550 kW

Capacity control method: slide valve

Control range: 15%–100% stepless regulation

Cooling method: air-cooled or water-cooled

Product Applications:

Natural Gas & LNG Industry: NG boosting and transmission, BOG compressors

Chemical and Industrial Process Gas Compression

CCUS (Carbon Capture, Utilization & Storage): CO₂ compressors

Waste Heat Recovery: Steam vapor compressors

Hydrogen Industry: H₂ compressors

Other Specialty Gases: Compressors for N₂, H₂S, etc.